Part 1 – Project Overview

Lead time

Shieldon, a knife manufacturer who has years of experience in the industry, recently collaborated with a famous knife brand.

This project was completed in a rapid 8 months time frame, allowing the customer to debut prototypes at an upcoming exhibition and begin selling during the high-demand hot season.

Shieldon worked hard to meet their customer’s expectations and pressed ahead with the production timeline, which included two months of designing, one month of prototyping followed by another for modifications before re-prototyping.

After this, they utilized three more months to complete mass production while still upholding quality control standards.

Despite the customer’s stringent guidelines and heavy oversight of production details, Shieldon persevered through every challenge and ultimately completed this project within the predetermined timeline.

How the project came

Shieldon Knives, a global brand recognized in countries such as the US, Canada, France, and Indonesia was entrusted to complete this project due to its positive reputation.

The customer firmly believed that the factory could produce remarkable results due to its long-standing reputation of excellence.

Shieldon Knives are renowned for its strength, practicality, fashion-forward design, and affordability.

Their models boast standard industry quality but also feature distinct features that set them apart from the competition.

As an OEM manufacturer, Shieldon’s priority is to meet customer needs with modern technology at the forefront of knife innovation.

When a novel issue arises during the project, thinking outside of the box is essential to produce solutions.

Not only that, but it can also be an opportunity for the Shieldon team of experts to grow and evolve as they work with Shieldon to solve any problem.

Even though it was a budget knife model, Shieldon put in every effort to make sure the job was done right.

Products purchased

Blade material: 14C28N

Handle material: Micarta

Total length: confidential

Weight: confidential

Main pivot hardware: T8 416SS

Assembly hardware: T8 416SS

Clip hardware: T6 416SS

Carry orientation: Ambidextrous

Ball bearing: Caged ceramic

Blade style: Drop point

Handle color: Black

Clip: Stamped deep carry

Clip finish: Blackened

Lock mechanism: Nested liner lock

Open way: Hole

Blade finish: Blackwashed; stonewashed; satin

Blade grind: Flat

Part 2 – Reasons why customers chose us

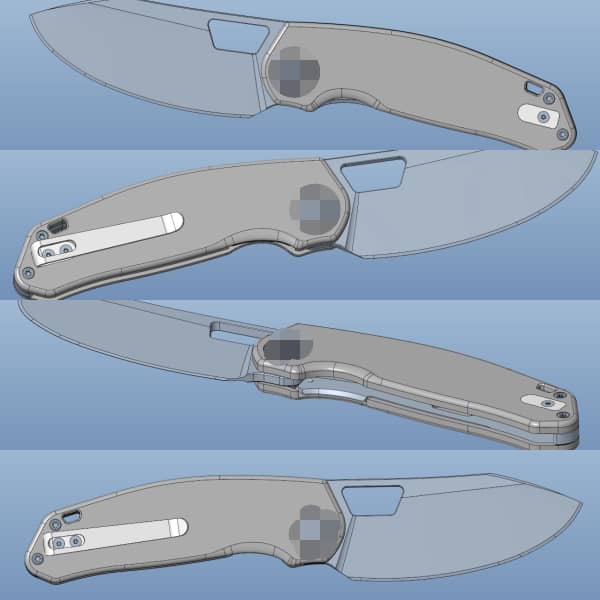

Design sketches and rendering images

Initially, the customer presented Shieldon with only a 2D graphic image featuring her brand name and model.

The experts at Shieldon were tasked with bringing this concept to life.

After careful consideration and multiple revisions, the experts of Shieldon spent two months perfecting their drawings before an additional month devoted to modifications after prototyping.

Initially, there were numerous unknowns due to a lack of requirements—forcing them to continuously inquire about what the customer desired out of their project.

For another thing, the customer changed the requirements several times during the discussion and making. Shieldon needed time to adjust and redo.

Shieldon was motivated by the customer’s eagerness which drove the team to move forward, and they were also lucky enough to gain insight into knife-making from the customer’s rich knowledge.

After a long process of confirming specifications, Shieldon experts could finally progress to their next step.

Packaging

Even though the customer’s knowledge of international trade was limited, she had extensive experience with knives.

Shieldon assured her that there was no need to worry as their team has many years of expertise with foreign trading and they even have an internal shipping division dedicated to handling all necessary customs clearance for international shipments.

Shieldon assured their customer that they can provide a comprehensive service, from 3D drawing to prototyping and manufacturing through to international shipping.

Their package is designed with an EVA tray lined lid-and-base box for enhanced security, plus they can print out any desired color code onto this package.

And what’s more – Silicon gel protection is also thrown in for free!

Shipment

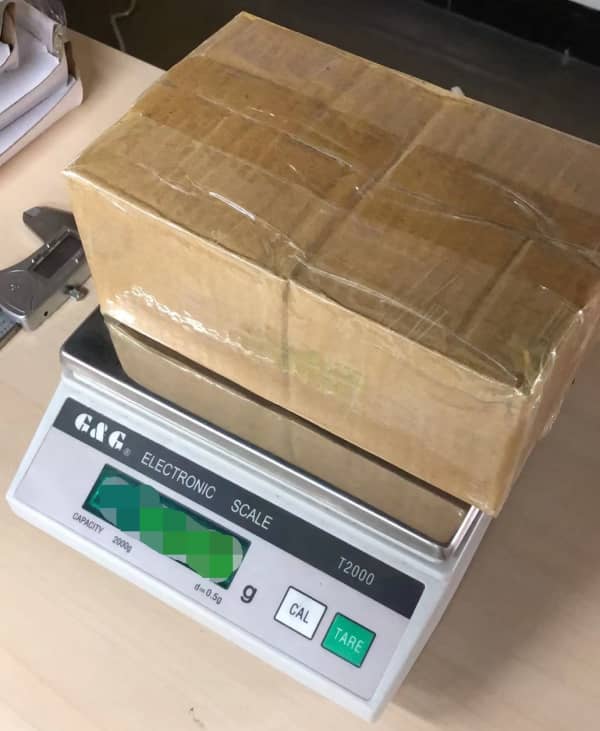

Initially, the customer had apprehensions regarding shipping; Shieldon allayed these concerns by sending photos of each package and its individual weight (12kg on average) during transit.

In total, twelve cartons were shipped to her address before she could finally rest assured that her finished goods had arrived in pristine condition.

Shieldon sent their products by air, usually through FedEx and UPS. However, the international air shipping policy dictates that all cartons must weigh between 12kg and 20kg.

Those weighing less than 12 kg will be charged for a full 12kg rate regardless of actual weight – an expensive affair indeed!

Each carton should be strategically filled to ensure it is within the 12kg and 20kg range, as this will help save money.

If a box exceeds 20kg, an additional fee will be charged – making it a costly financial loss.

Therefore, you must possess the skill of allocating goods in each carton effectively.

Shieldon experts are devoted to helping customers save unnecessary expenses.

Furthermore, to help customers identify the items inside the carton, experts typically list down information such as item name, number, weight, quantity, and size on the box.

This ensures that customers are aware of what they have received when their package arrives in perfect condition.

The professionals make sure all orders are carefully managed so they get exactly what they were expecting!

Part 3 – Story of the manufacturing process

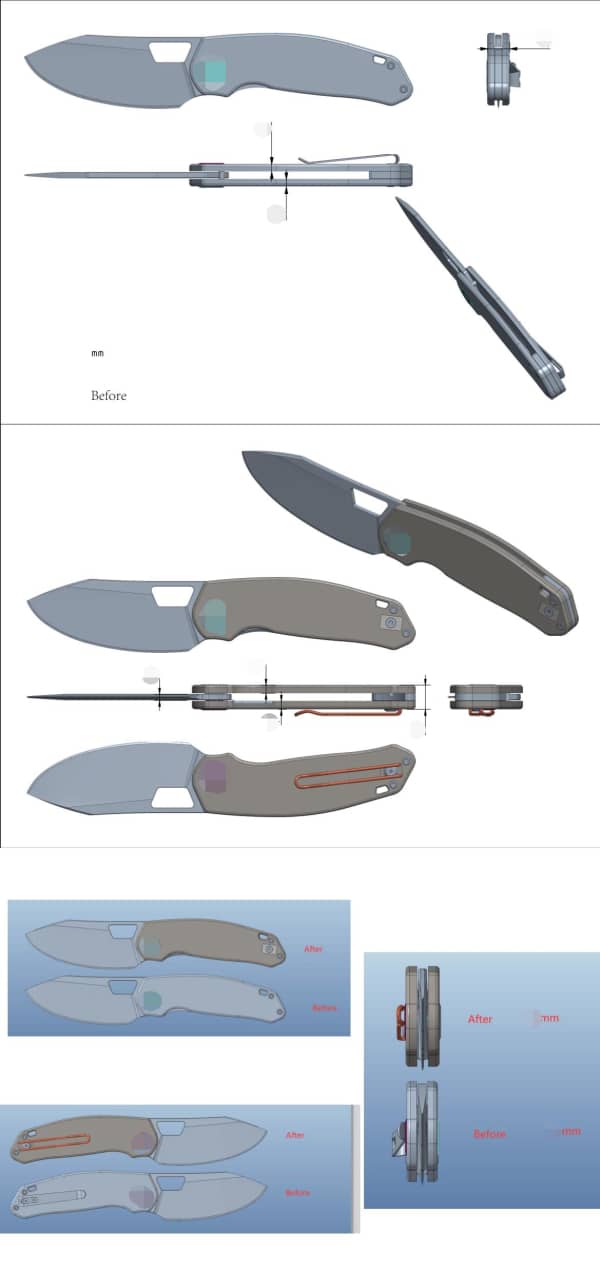

With only a 2D graphic image of the requested OEM product, Shieldon experts had to start from scratch when it came to creating the design.

They used CAD software and worked together with the customer on each step of recreating the item until both parties were satisfied with its final look.

The client provided some data to the Shieldon staff after several letters back and forth.

As a first step, the fastener should flip so that the screw thread is accessible from either side of the handle.

Second, Shieldon knew that the handle frames couldn’t be exposed, so they used a layered design to hide them within the scales.

Thirdly, the outer edges of the scales have been rounded off to give them a more polished appearance.

Finally, the client requested a filling tap on the gauge to hide the screw hole for the side clip if it isn’t fitted.

After further discussion, Shieldon began to formulate plans for producing the object.

In conclusion, Shieldon experts can meet client requirements, but only if they are communicated.

During each production run, they tailor the blades and tools they create to the specific requests of their clientele, with Shieldon occasionally borrowing their ideas.

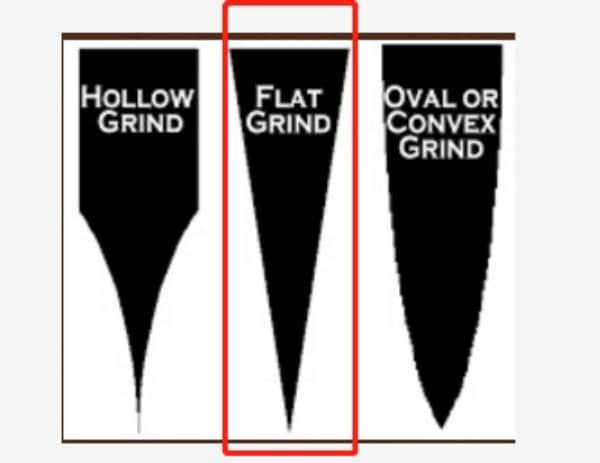

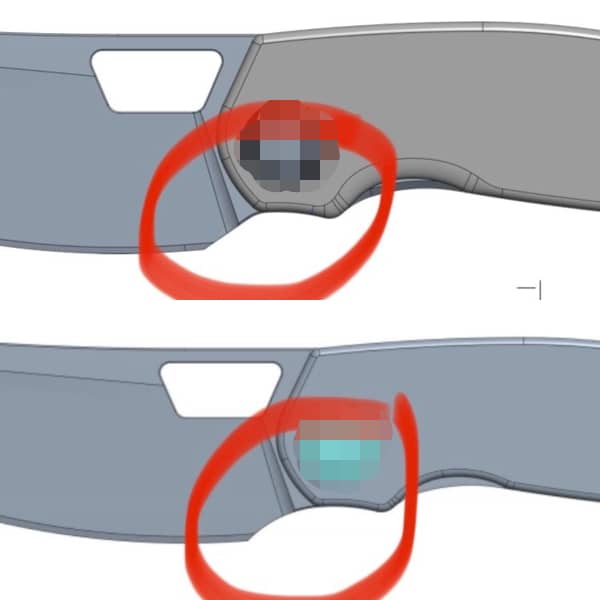

Shieldon’s team of professionals spent quite some time debating the blade grind for the item, with the customer specifically requesting a hollow grind.

However, it was impossible to fulfill this request—so they suggested a flat grind instead.

The customer hesitated because they were unsure if it would provide enough sharpness; that being said, Shieldon assured them that its razor-sharp edging would meet all expectations!

Shieldon was unable to hollow grind this item due to the blade’s width.

As detailed in the accompanying image, there is a restriction on how wide a blade can be hollow ground without compromising its length and curvature.

Therefore, water milling had to be employed instead for optimal performance and craftsmanship.

The flat grind of the water milling line can reach up to almost the top of its backspine, while a hollow grind typically only reaches so far as beneath the hole.

This shift in blade design also shifted belly widths with it – all thanks to the remarkable power of water milling!

They explained that the current technology was insufficient to meet their customer’s needs, and eventually she conceded and opted for a flat grind.

Of course, Shieldon guaranteed they would achieve maximum sharpness.

After discussing the design, it was evident that a wire clip wasn’t necessary for accurate scale readings.

Shieldon then presented the customer with multiple images of stamped stainless steel deep carry clips which he deemed more appropriate for their project.

This sparked another debate about what kind of clip to use in this particular instance.

The Shieldon team had an intimate understanding of the customer’s needs and devoted their efforts to catering to their requests, yet they also provided them with a professional experience in terms of production.

The wire clip was not aesthetically pleasing and easily bent.

Structural imagery demonstrated the size of this item, but in reality, it wasn’t sufficiently durable for frequent usage.

Instead, consumers opted for a stamped stainless steel deep carry clip that provided additional pleasure by allowing them to switch from right-handed holds to left-handed ones with ease.

After demonstrating Shieldon’s expertise, the customer agreed to use a stamped clip.

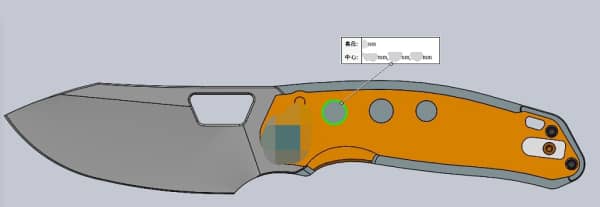

The ball-bearing system was a matter of great concern to the customer.

They frequently utilize a single-caged ceramic ball bearing in their folding knife pivots, measuring 9.56mm in diameter – as demonstrated by the image.

Furthermore, each ceramic ball inside its cage has been carefully examined and found to measure 1.58mm respectively; rendering the client satisfied they were dealing with true professionals who take quality control seriously!

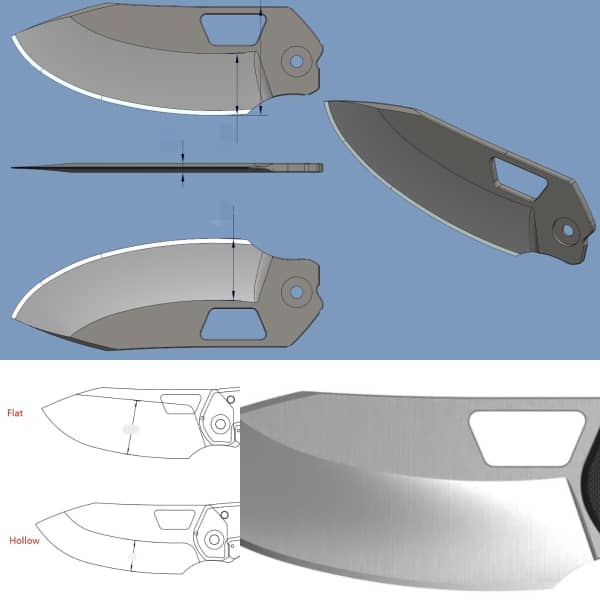

Following multiple talks and alterations with Shieldon, the customer’s original descriptions, and specifications were altered.

Consequently, it was essential to create a new version of the plan before proceeding with prototyping to affirm all details adequately.

When negotiating an OEM item, it’s essential to ensure that the final agreement and description are regularly updated; otherwise, all of your efforts could be wasted.

Shieldon dedicated two days to ensuring accuracy, reviewing their conversations, and updating the drawing with all relevant data.

The customer diligently read through the final copy for confirmation of all details before approval.

The photos included here demonstrate the dramatic transformation that occurred before and after the modifications.

After verifying all the particulars, Shieldon moved on to constructing a prototype.

Each individual part was crafted apart from one another: blade, liner, scale, clip and any other components necessary for assembly.

Crafting prototypes is quite different than mass producing them – it’s an art form of its own!

When it comes to prototyping and mass production, the former requires more time for data testing and material testing by an individual.

Whereas with mass production, materials, as well as team personnel, must be arranged.

There can be no comparison in terms of quality between prototypes and large-scale manufacturing processes.

Thus expensive materials are usually not used for prototyping since tests might cause a waste of resources.

Constructed with multiple sections, this Micarta scale is coated in a sleek black hue.

Known for its unparalleled strength and durability, this thermoset plastic can withstand drastic shifts in temperature while remaining impervious to moisture and aging over time.

Consequently, knife handles made of Micarta are highly reliable when it comes to long-term use – even under the toughest conditions!

The blades were cut by liner cuts machines and subsequently required CNC processing, water milling, blade finishing, and edging.

As only one worker is following the entire prototyping process – taking time to carefully record every data before mass production in the future – it can’t be rushed despite requiring much energy.

After a month of intensive prototyping, Shieldon had crafted 8 individual pieces.

To ensure quality and reliability, they sent 6 to the customers for inspection while keeping 2 as a backup in case any changes needed to be made later on.

The experts packed with meticulous attention to detail, as the car was a symbol of two brands: one for the customers and another for Shieldon.

Shieldon knew the customer needed it before their exhibition, so they chose DHL to send as quickly as possible.

Although pricey, international delivery via DHL was necessary for the timely arrival of the package.

If you’re shipping internationally with DHL, there’s a savvy trick to save on costs: they charge for each 500g incrementally.

The clever folks at Shieldon are mindful of this and make sure their packages are as lightweight as possible — just take the photo included here as proof!

Unfortunately, due to nondisclosure agreements, they can’t show exactly how much they weigh.

After despatching the DHL delivery, customers usually receive their items within seven days.

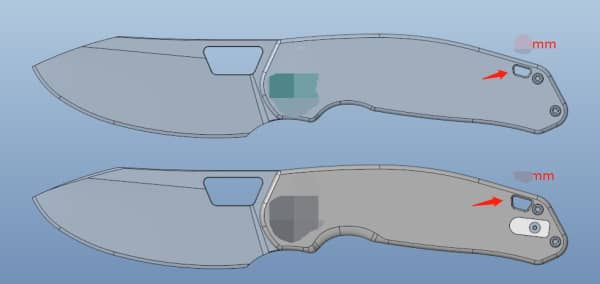

To their surprise, two weeks later they received many positive comments and reviews about the exhibition with mass production ready after several modifications from prototypes to final products.

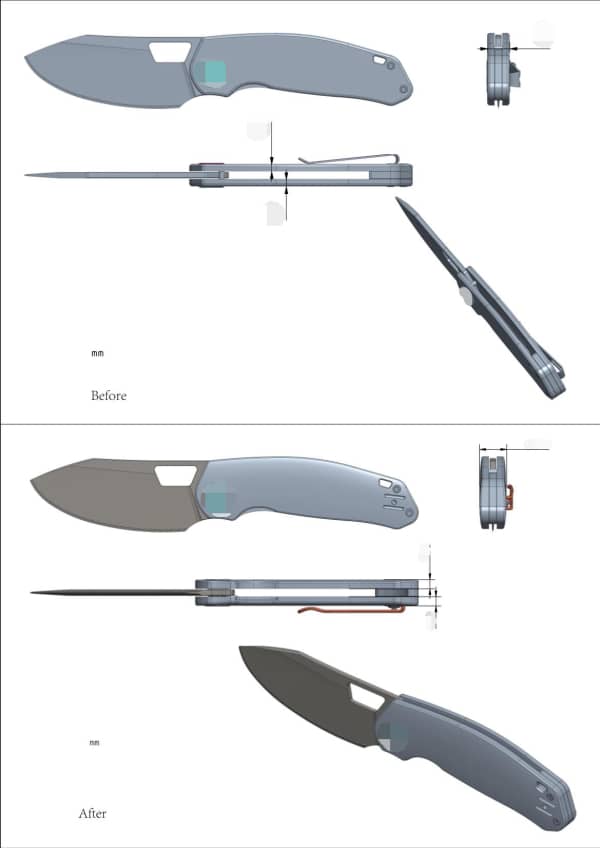

To start, Shieldon team should increase the size of the thumb-release scale to enhance user comfort when disengaging.

To guarantee consistent quality and performance, Shieldon makes certain that every original equipment manufacturer (OEM) or production run is prototyped.

As an OEM manufacturer, Shieldon understands that maintaining a clear and objective mindset can help them stay away from overly investing in consideration.

An additional area that needed adjusting was the lanyard hole, which didn’t accommodate the overall scale size of Shieldon.

So they enlarged it for a better fit. This demonstrates just how essential prototyping is in an original equipment manufacturing (OEM) project.

Moreover, to save weight the liners must be skeletonized during every production; this was a crucial detail that they identified early.

This issue revealed the customer’s expertise.

The plunge grind should be pushed back and just beyond the edge termination, which was difficult to determine but did not seem similar to that of the original prototypes.

Additionally, the customer requested for both sides of the grinds to be evened out for a more uniform look.

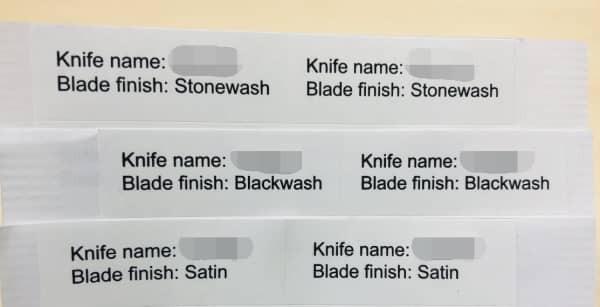

After several rounds of conversations, the customer finally decided on 3 finishes for their blade: satin, stonewash, and black titanium coating before stonewash (also known as “blackwashed”).

Accordingly, all changes made to the CAD files were updated accordingly.

To verify these modifications and ensure satisfaction with the product design, new rendering images were created.

After a meticulous review of all specifications that had been modified over the past five months, Shieldon and the customer both ensured each detail was taken into account.

Every email message was double-checked to make sure nothing important went unnoticed; eventually, with satisfaction on both sides, the customer signed off on the production agreement and paid their deposit – allowing Shieldon to initiate mass production.

Shieldon is a renowned OEM manufacturer of outdoor knives and tools, adhering to exceptional quality assurance standards—you can trust that all of the Shieldon Knives models have been held to this same high-caliber threshold.

Production on a large scale began during the project’s initial six months. After figuring out how many blades, liners, scales, and clips were needed, the next stage was construction.

Because of the potential for wear and tear during manufacturing, it is standard practice to make all components 10% larger than the client requested.

When one part fails, the others typically make up for it. Shieldon must maintain tight manufacturing controls at every stage if it is to fulfill every buy order and minimize losses.

Knives are typically crafted from steel, which is not easily destroyed but is instead abandoned once it has been broken.

The pros and cons of various materials vary. Shieldon, as an Original Equipment Manufacturer, places a premium on quality raw materials and provides cost-cutting assistance at every stage.

Pay close attention to the detent hole, not the attractive nail of my sales representative. The blade has a small circular ball bearing set into the corresponding side of this opening.

Securing the detent ball in place when closing is considered a satisfactory detent, however, this does not guarantee its quality.

A detent functions as an effective tool to stop or impede the rotation of your knife blade.

The images showcased the skeletonized liners from Shieldon, and you may notice that some holes were cut into the steel to reduce weight.

By removing any nonessential parts in these liners without compromising their purpose, they could be as light yet strong as possible. This makes them ideal for knives!

Don’t be deceived by the 10g weight savings that a skeletonized knife has in comparison to its non-skeletonized counterpart.

The average 8-inch EDC folding knife regularly weighs between 100-150g, which means skeletonizing can decrease the weight of an EDC Knife by up to 10%.

These images showed the segments.

Without thermal treatment, the clip is pliable or even malleable. Therefore, once the clips were bent into a fixed shape, Shieldon subjected them to thermal treatment, rendering the bending shape permanent and irreversible.

The surface is then finished after thermal treatment.

Regarding blade finish, the customer asked for three distinct finishes – satin, stonewash, and blackwashed (black titanium coating before stonewash).

As there is no empirical standard when it comes to these finishes, Shieldon typically sends photos of each version over to their customers for confirmation.

To create a stonewash finish, blades are placed in a basin-shaped machine and exposed to crashing stones for several minutes.

This novel knife industry technology results in each piece having an individualized wrinkle-like pattern on the surface which cannot be controlled or predicted.

Shieldon sent several pictures to the client, prompting them for a thorough inspection. The combination of stonewashed and blackwashed patterns was truly splendid when completed!

The Shieldon team posed the question of whether or not it would be necessary to etch logos and other information onto the blade, although the customer desired for their product to remain sterile.

As stated, Shieldon also assists with package packaging design. This was a lip-and-base package, similar to that of the iPhone.

The color required a CMYK code. Shieldon provides end-to-end service, from the 3D design of an item to its production, packaging, and shipment.

Shieldon argued that it would be more beneficial to insert an EVA tray with a velour surface inside the box.

To best illustrate what they meant, they provided this example of a package constructed beforehand.

Shieldon professionals crafted the tray specifically to fit the customer’s product, and they wholeheartedly agreed with this idea.

During the knife-making procedure, a prototype of the packaging case was also created. Shieldon sent the consumer a few photographs.

As it was simple to verify and did not require a thorough examination, the experts were not required to submit it for verification.

The shape of the EVA trap was an excellent match for the genuine item. The packaging is identical to that of the iPhone.

This was the opposite side of the shipping carton.

Shieldon created a blade finishing label and affixed the email address because the customer did not want the email address to be visible.

Once the components had been prepared, Shieldon began to assemble each knife systematically. This process took an entire week in total.

The experts at Shieldon rigorously tested and amended various prototypes of the OEM model to find out the optimal detent on pivot points and ergonomics for its overall profile.

Once they had unlocked the ideal assembly conditions, the team of professionals moved forward with mass production.

This sample failed to meet the customer’s requirements.

The alignment wasn’t spot-on; the detent lacked power; and the screws were not finished with a satin coating.

Shieldon is renowned for its swift, dependable detents. Rest assured that the product will be reassembled until you are completely satisfied with the condition of this model.

Shieldon pulled the sample apart and modified each place/part meticulously until finding the finest state of the model.

The specialists assured the client that he would not have to stress about output.

For one reason, adjusting requires time, which cannot be rushed. For another reason, rushing over and getting things incorrect becomes too much.

After conducting various experiments in the lab, Shieldon was able to determine the optimal level of strength for the locking mechanism and also identify a profile that is suitable for all types of knives.

After completing production, the Shieldon team dutifully sanitized the knives before packing them away. A few pieces still remained in place, however.

Part 4 – Shipment and Summary

The Shieldon workshop team proudly showcased their mastery of craftsmanship when the bespoke knife was finished, demonstrating that even a job as complicated as this one could be executed with distinction.

Exceeding customer expectations is their highest priority!

Shieldon figured the most efficient way to differentiate their model’s three finishes were by printing out labels that say each respective finish and sticking them onto the box.

This makes it easy for customers or consumers to identify which product they’ve chosen at a glance, eliminating any confusion or frustration.

In addition to the labeling, Shieldon also took customers’ packaging into consideration.

To prevent items from being damaged by humidity in various climates, they suggested putting a silicon gel inside each box and wrapping it in a polypropylene bag for extra protection.

Initially, the Shieldon professionals inquired as to whether the customer preferred shrink-wrap packaging; however, after being informed of its difficulty in verifying goods upon arrival, it was decided that polypropylene bags would be the most suitable option.

Shieldon discovered that after this project, they had all gained expertise, whether it was in production management or timetable organization.

During these years, this was part of an unforgettable OEM effort.

The customer’s brand is well-known in the cutlery community, and knowing who OEMs the brand is also beneficial to the Shieldon brand.

Adhering to the global shipping regulations via air or sea is imperative for Shieldon, as not doing so can result in expensive shipments and even potential inspections from customers.

Shieldon’s customers often don’t need to be aware of the rules or regulations associated with the shipment process.

As an OEM manufacturer for years, Shieldon’s team of experts is dedicated to ensuring a smooth and worry-free delivery experience for all global customers.

In some cases, they can even assist in alleviating any applicable tax burden when importing goods into other countries.

After 8 months of collaboration and progress, the Shieldon team is delighted to ship a total of 12 cartons worth of goods directly to the customer’s country.

As Shieldon accumulates additional OEM experience in the production of quality knives and tools, its reputation as an industry leader continues to expand within the knife community worldwide.

At Shieldon, they embrace challenging projects and are accustomed to the diversity of cultures. If you’re interested in having your custom project created by a team of experts, don’t hesitate to reach out!

Click on the customer’s website for more information: https://divoknives.com/

If you want more fun on Shieldon EDC entertainment, click their social media below:

Shieldon、Facebook、Instagram、YouTube、Twitter、Pinterest

Thanks and see you next time!