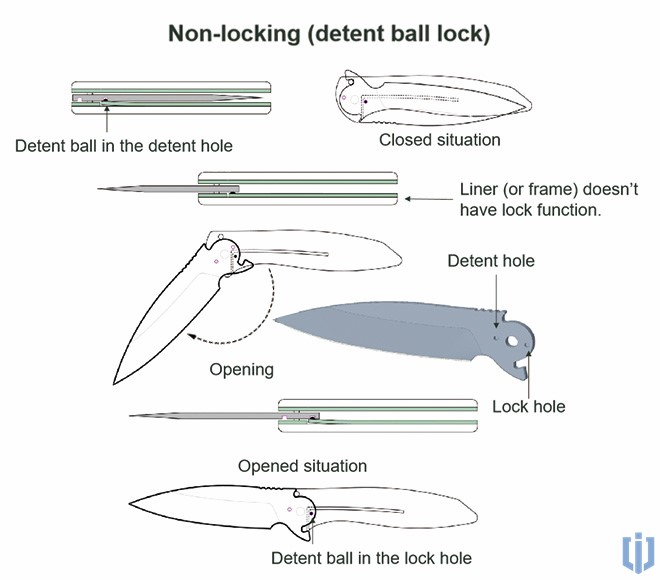

Non-locking mechanisms, often found in folding knives, multi-tools, and other hand tools, function without the presence of a traditional locking system, allowing for easy opening and closing of the blade or tool. These mechanisms typically rely on friction or tension to keep the tool in the open or closed position, making them user-friendly and straightforward. While they may not offer the same level of security as locking mechanisms, they are prized for their simplicity and quick accessibility. Within this classification, businesses and clients have the flexibility to choose the non-locking mechanism that best suits their product requirements. Shieldon, as a trusted OEM/ODM manufacturer, provides valuable expertise in selecting and integrating non-locking mechanisms into products, ensuring that they meet the desired functionality and safety standards for a wide range of applications.

Popular science highlights non-locking systems’ simple yet useful design. Folding knives and multi-tools employ these systems without locks. Instead, they use friction, tension, or slide joints to secure the blade or tool for one-handed use and rapid access. They may not be as secure as locking systems, but their simplicity and use make them appealing among individuals who value convenience. Non-locking mechanisms are reliable in regular work and utilized in many EDC items. For folding knives and multi-tools that are simple and fast to use, understanding the popular physics underlying non-locking mechanisms is key.

Shieldon is your trusted source for excellent non-locking lock mechanism options, delivering a range of features and benefits to enhance your product offerings. When you choose Shieldon, you can expect.

Shieldon provides invaluable expertise in the selection and integration of non-locking mechanisms into your products. We guide you through the process to ensure that the chosen mechanism aligns with your specific design and performance requirements.

Shieldon's non-locking mechanisms are crafted with reliability in mind. We ensure that your products will perform consistently and securely, meeting industry standards and safety requirements.

We understand the importance of cost-effectiveness in product development. Shieldon offers competitive pricing without compromising on quality, allowing you to access premium non-locking mechanisms while maintaining profitability.

Shieldon is committed to ensuring that our non-locking mechanisms comply with industry regulations and safety standards. We work to ensure that your products are not only reliable but also legal and safe for use.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.