Quality

Making knife is taken seriously right from our material sourcing process. Our broad suppliers network accumulated by decades of experience in the industry gives us access to various material suppliers that help us to get the best material possible for our clients.

Besides, every batch of material shipped to Shieldon factory is subjected to the incoming quality check before they are approved to be used in the manufacturing processes.

From stamping to packaging, each step follows the standard operating process and will weed out those parts that are not complying with the standards.

Defective steel sheet caused by improper stamping force.

Blades not reaching the right hardness as per specification.

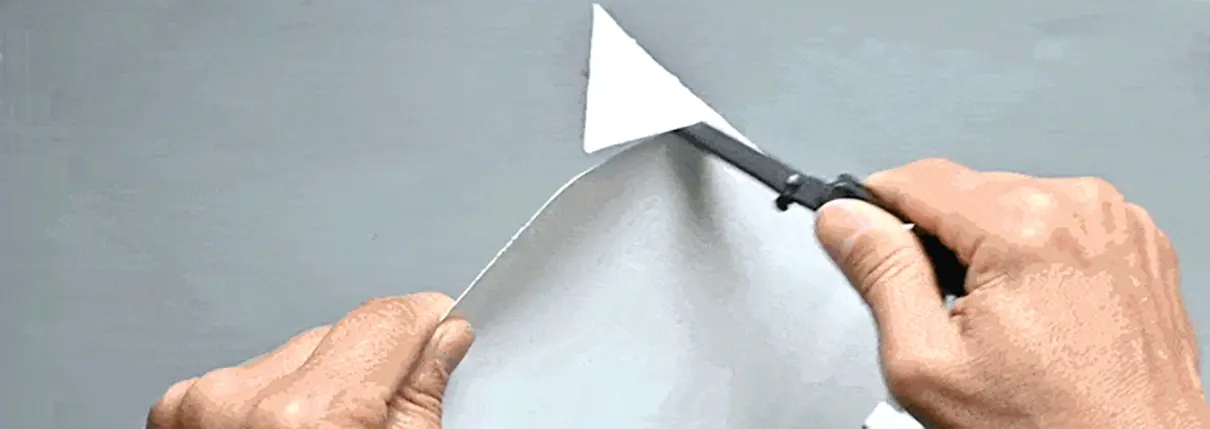

Blades with rough edges or fur after milling.

Not holding sturdy against the sand blaster for both side.

By randomly inspecting 10 knives out of 100, we won’t let go any batch of knives estimated under 99% pass rate.

Subjected to high standards, all of our inspection on the finished knives are conducted in a specialized work station with 300-700 Lux lighting. The examiner is required to inspect the knife for at least 30 seconds, ensuring the knife functions properly, looks flowless and was assembled as per specification.

We are ready to help at any stage of your OEM knife project. Send us your enquiry and your budget and we will get back to you within 24 hours.