Part 1 – Project Overview

Lead Time

Over the course of 9 months, our professionals spent 2 months communicating through email and video chat on the 3D drawings, another 2 months on the prototype and delivery stages, 3 months on the mass production phase, and the last month on packaging and shipping.

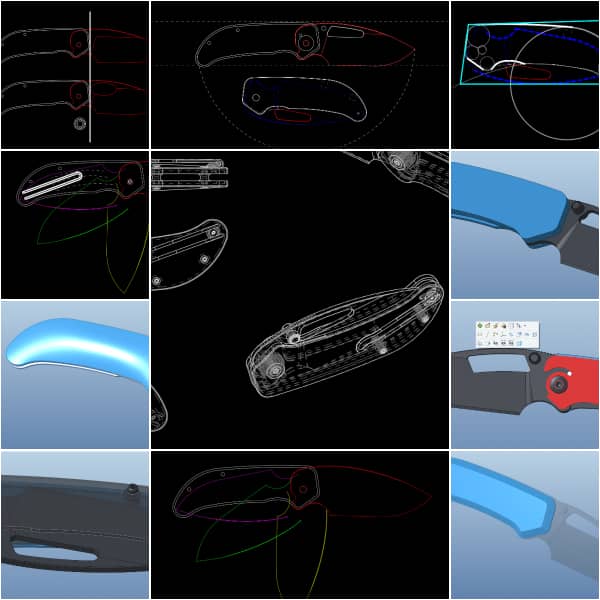

In the design phase, Shieldon’s expert team provided insight into how the product may better meet the needs of the target audience, and the final product was based on client specifications.

Shieldon designed and printed the packaging since the client didn’t know where to begin with either the packaging itself or the printing process.

This customer was unfamiliar with international payments and shipping, but thanks to Shieldon’s comprehensive approach, the difficulties were handled promptly and without difficulty.

With Alibaba’s Trade Assurance and Door-to-Door service, a buyer doesn’t have to worry about making payments or having their packages delivered on time.

How the project came

Shieldon was a reliable business partner to the fledgling knife manufacturer.

Shieldon assisted the client with professional product drawings and renderings, materials displays for selection, prototyping, and DHL delivery, package design, instructional paper printing, custom name card graphic design, serial production, carton packaging, DDP shipping to various locations, customs clearance, etc.

From initial graphic design to finished product shipping, Shieldon’s service met the client’s expectations.

Despite his preliminary research into other manufacturers, the customer relied entirely on Shieldon’s competence and service.

Custom products purchased

- Blade material: 14C28N

- Handle material: Micarta

- Blade HRC: 58-60

- Sharpened angle: 15-20 angle

- Main pivot hardware: T8 416SS, D-shape

- Assembly hardware: T8 416SS

- Clip hardware: T8 416SS

- Carry orientation: Right hand

- Ball bearing: Multi ceramic ball bearing

- Blade Style: Drop point

- Handle color: Royalblue Pocket

- Clip: Wire Tip

- Clip finish: Blackened

- Lock mechanism: Nested liner lock

- Open way: Thumb stud + hole

- Blade finish: black titanium coating with stonewash

- Blade grind: Flat

Part 2 – Reason why the customer chose us

Quality

The client requested a custom pivot and stop-pin, which the expert team was able to provide.

The client detailed not only his wants but also his dislikes, which he requested our professionals to remember.

Given how simple this criteria was, our experts didn’t feel the need to provide any more information.

With this modification in place, our team was able to arrive at reasonable prices.

The drawing was changed several times so that the final product would meet or exceed the expectations of the people we were trying to reach.

During the 100 days it took to make, both the inside and outside of the structure were fine-tuned.

The client had a clear idea of how the knife should look, but when the team asked for a product concept or product draft, the customer was still in limbo.

So, our experts explain again what tools and resources we have at our disposal. The customer felt better as soon as he bought one of our Shieldon models on Amazon.

Our work is done, and the client is happy with it. In his mind, a clear picture of how the knife would end up took shape.

Almost every part of the customer’s vision was carried out, and the general profile stayed the same. However, our experts made a few changes that made the product better.

The buyer asked for modifications to be made to this folding knife, such as the blue Micarta handle and the multi-ceramic ball bearing.

Packaging

The customer’s new brand needed the basic concept for its packaging.

We presented numerous common box types, and the clamshell design ultimately won out.

We assisted him in developing the prototype for the box as well as the accompanying instructions. Our printing service was another one of his favorites. He was pleased with our package design and printing service in addition to our metal production capacity.

Packaging and transportation

Our team assisted the client with international payment and shipment, as well as double customs clearance since the client was unaware of what international commerce is and what paperwork needed to be presented.

Our client was able to make the final payment and arrange for transportation thanks to Alibaba’s Trade assurance Order and door-to-door service.

The customs agent was pleased with our logistics service since all he had to do was wait for the products to be delivered to the house.

Part 3 – Story of Manufacturing Process

Our CNC machines produce the vast majority of the necessary parts. It’s common knowledge that this machine is precise yet ponderously slow.

All three components, scales, liners, and blades, are distinguishable to within 0.1mm.

However, it is limited to producing just 20 pieces of components every day because of its sluggish operation. Therefore, this order must be processed slowly.

Our team sought the client’s opinion on a particular item, and our specialists presented him with several swatches in various shades, and he was especially taken by one of them. He had praise for the task that we did.

They were aware of the significance our team placed on his output.

The Shieldon group also modified the production workout from the prototype.

There must be some distinction between them since the techniques and procedures that they use are different.

In general, our team keeps the prototype process distinct from the production process.

This is because, in order to maximize both material and labor efficiency, the workshop sets up distinct working lines for each activity.

A jimping was added to the blade spine of the production model, which is one of the differences between the prototype and the production model.

The client expresses the desire that individuals would experience some friction when they catch and utilize the knife.

Our group swiftly made the necessary adjustments to the procedure and eliminated the jimping via line cutting.

The jimping is quite apparent to notice. When the thumb is put on the jimping, it provides a more stable cutting experience for the user.

When all of the components for the knives are ready, our team put them together one at a time. The use of several ceramics in the ball bearings is both a selling point and a challenge.

Due to the fact that the bearing only attaches to the pivot and does not provide any excess space, the worker had to construct it with extreme care and delicacy.

If the bearing is moved to the side even slightly, the pivot will no longer function properly.

As soon as the knives had been put together correctly, our specialists went over each one and tested its functionality, examining things like the opening mechanism, the blade’s sharpness, any defects in the look, and so on.

The members of our team carry out this procedure with great care. And this is precisely why the client enjoys having Shieldon create knives for them.

When there are no issues with the knife, we finished putting the attachments on it before cleaning it and packaged it right Qt.

The first of them is a stud for the thumb. Experts usually install it at the end because it doesn’t require a lot of expertise and doesn’t affect how the whole method works.

The second part of the accessory is the wire clip. We have to put it in last because it will get in the way of the knife inspection.

If one of our professionals identified a component that had a defect, a specialist would remove it from the configuration or assembly and make the necessary adjustments.

The specialists of Shieldon are tasked with ensuring that the problem proportion is lower than 3%.

Because the blade is not always centered and flat, our specialists have to use the machine to bring it into alignment so that it is centered and flat.

The inspection of the items requires both patience and expertise.

Shieldon is expected to produce a positive first impression on the customer when the things are delivered, thus our staff meticulously looked over each product and cleaned it individually with special alcohol before carefully packaging it.

The knife is finalized at this point. The final version should be far better than the prototype.

The materials for the packaging were also prepared and included a name card, instruction paper, and an exterior PP bag in addition to a clamshell box that had a sponge pallet on the inside.

Our experts talked with the client about whether or not to put this sticker on the seal. The client wanted to check the items after they were delivered, so our experts decided not to use them.

These stickers were only included in the shipment that was delivered to the client.

The items are packed inside each box before being placed into the carton.

The client requested that Shieldon ship their items to two separate nations, which is a little bit of a challenge given that shipping internationally is not the same as shipping inside the country.

Our team is required to hand in the product documentation and customer PI, as well as make the necessary arrangements for the shipping agency and the customs claim.

However, in order to fulfill the requirements of the client, our specialists put in a further effort to find a solution to this issue.

Part 4 – Shipment and Summary

A clamshell box with a sponge pallet inside, a document with instructions, a name card, and an outside PP bag were also prepared.

We asked the buyer whether we should put this sticker on the packaging, but he wanted to inspect the goods after getting them, so we did not.

We recently delivered these stickers together with the shipment to the client.

The products are packed into each box prior to packaging. As previously said, we treat our goods with immense care.

The client requested that we ship his items to two separate countries, which is a bit of a challenge given that international shipping is unlike local shipping.

We must provide production and customer paperwork, as well as arrange for a shipping agency and customs claim.

However, in order to fulfill the customer’s request, we will work additional hours to overcome this matter.

That’s it! If you are looking for a reliable OEM provider, Shieldon is here for you. We have years of experience helping various clients to meet their needs and expectations.

Contact us today to know more!

The customer’s website is for your reference:

https://canadianknifecompany.com/

Click to have more Shieldon EDC knives and tools fun.