The Production Process of a Folding Knife

Making a high-quality folding knife is no simple task. It’s a meticulous process that involves precision, skill, and advanced technology at every step. From crafting the blade and handle to assembling the final product, every detail matters to ensure durability, functionality, and safety. Whether you’re curious about the craftsmanship behind folding knives or want to understand how […]

Packaging Production Process

Every great product needs great packaging. The Packaging Production Process shapes how your pocket knives, multi‑functional tools, and outdoor gear arrive safely—and look irresistible—on store shelves and doorsteps. At Shieldon, leading custom tool manufacturers and wholesale knives suppliers, we know that a seamless packaging journey turns first impressions into loyal customers. In this article, we’ll walk […]

Multi-tool Manufacturing Process

Imagine a craftsman shaping metal and composite, one stroke at a time, forging a versatile multi-tool that fits in your pocket. The multi-tool manufacturing process brings together materials science, precision engineering, and cutting-edge inspection methods to create a reliable everyday companion. From selecting aerospace-grade alloys to laser-assisted positioning during final assembly, every step ensures performance and […]

OBM Brand Distribution

At Shieldon, we believe that knife quality means life. With countless years of experience, we don’t just make knives, we craft reliable everyday carry tools that meet the highest international standards. We know the market changes fast, so we stay ahead by combining the latest manufacturing techniques with deep technical knowledge. If you want to […]

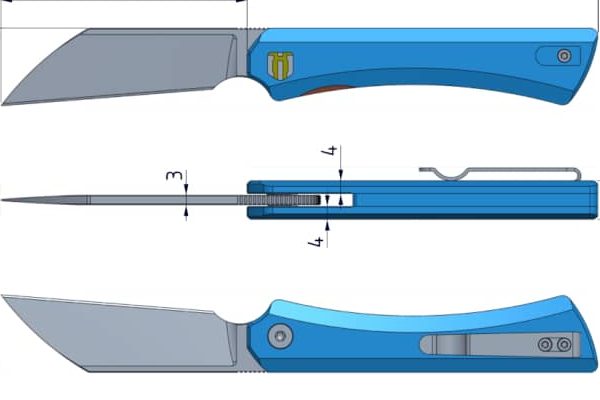

A Comprehensive Guide to the Product Development Process at Shieldon

Shieldon offers a clear and efficient product development process to bring ideas to life. Starting with a confidentiality agreement, each stage is carefully managed to ensure quality and meet client requirements. The process begins by confirming product needs like functionality, materials, and certifications. Detailed design and engineering follow, including 3D modeling, material selection, and prototype […]

Unveiling the Masterpiece: Witness the Mesmerizing Creation of MP01 Blacksmith Rain

Story of the Manufacturing Procedure of Mp01 Blacksmith Rain Michael Pretsch and the Birth of Rain – Shieldon’s Iconic EDC Knife” In a realm where knives are more than just tools, a charismatic designer by the name of Michael Pretsch emerged. For the past five years, he delved into the art of knife design, crafting […]

The Comprehensive Design Process of the Blacksmith Hierophant MS01A Knife

The Blacksmith Hierophant MS01A Knife is a unique and innovative product, designed and crafted with the utmost attention to detail by Matthew Szymanski and Shieldon. The design process was comprehensive and incorporated both traditional techniques as well as modern engineering principles. From the selection of materials to the final testing and polishing, every step in […]

Shieldon and Eric Garza’s Process in Making the Blacksmith Viper EG01A Knife

As professional knife users and manufacturers, Shieldon and Eric Garza understand the importance of having a quality knife. Knife users need knives that can handle any situation, while knife manufacturers need knives that can be put through rigorous testing without fail. That is why they have teamed up to create the Blacksmith Viper […]