Every great product needs great packaging. The Packaging Production Process shapes how your pocket knives, multi‑functional tools, and outdoor gear arrive safely—and look irresistible—on store shelves and doorsteps. At Shieldon, leading custom tool manufacturers and wholesale knives suppliers, we know that a seamless packaging journey turns first impressions into loyal customers. In this article, we’ll walk step by step through each phase of packaging production, from understanding customer needs to final delivery. Get ready for an engaging, friendly deep dive—no jargon left unexplained, plenty of real‑life examples, and even a dash of humor.

“Good design is obvious. Great design is transparent.” —Joe Sparano

Let’s unwrap the science, the art, and the tiny details that make packaging both protective and persuasive. After all, how your folding knives arrive tells customers as much about you as the tools themselves.

Requirements Analysis & Compliance Pre‑Review (3–5 days)

Before any scissors touch the paper, we map out exactly what the packaging must do—and what rules it must follow.

- Customer Needs Assessment

- We clarify functionality(Is it for retail display or heavy‑duty transport?).

- Next, dimensions, materials, quantities, and specific packaging types (e.g., color box, blister pack, tin box, gift set).

- We ask, “Who’s buying this?” and factor in target‑market regulations—say, the new EU Packaging and Packaging Waste Regulation (PPWR) that replaced Directive 94/62/EC on January 22, 2025.

- For California markets, we check Proposition 65 to warn of any chemicals causing cancer or reproductive harm.

- Compliance Assessment

- Eco‑material certifications: FSC‑certified paper, biodegradable plastics.

- Printing inks: Must be REACH/ROHS‑compliant and heavy‑metal free.

Example Table: Initial Requirements Snapshot

| Requirement Type | Details & Standards | Reference |

| Functionality | Retail display vs. transport protection | Shieldon delivers both with custom solutions |

| Dimensions & Materials | e.g., 350 g art paper; PET blister 0.5 mm–0.8 mm | FSC, REACH |

| Packaging Types | Color box, blister pack, tin box, gift set | Internal library |

| Regulations (EU) | PPWR (effective Jan 22, 2025); EPR schemes | khlaw.com EUROPEN |

| Regulations (CA) | Proposition 65 warnings | OEHHAQIMA Blog |

| Eco‑certifications | FSC, biodegradable PLA inserts | Tetra Tech Sustainable Markets |

Tip: Think of this phase like planning a road trip: you figure out where you’re going, what vehicle you need, and which toll roads (regulations) you must pay.

By locking down these details in 3–5 days, Shieldon ensures every custom knife and tool ships in packaging that’s legal, green, and on‑brand—without surprises down the line.

Design Development & Client Approval (5–7 days)

Once requirements are locked in, it’s time to bring packaging to life—melding branding, function, and user delight.

1. Brand Element Integration

Packaging isn’t just a box; it’s a billboard for your brand. Designers work in Figma or Adobe Illustrator to align visuals with your VI system—Pantone‑matched colors, licensed fonts, and logo placement that stands out in a sea of shelves. Real‑time collaboration tools like Figma speed up feedback cycles and shrink approval times to days rather than weeks Filestage.

Analogy: Think of your packaging as a movie poster—every color, font, and image must shout “pick me!” at a glance.

Table: Brand Integration Checklist

| Element | Details | Tool/Standard |

| Color Matching | Pantone spot colors vs. CMYK conversion | Pantone Connect, Pantone® Guides |

| Fonts | Licensed branded fonts | Adobe Fonts, Monotype |

| Logo Placement | Front, back, sides—ensuring visibility at point of sale | Client VI manual, mock‑up reviews |

| Imagery | Product shots, lifestyle scenes | High‑res photos (300 dpi), background removal |

| Collaboration Platform | Live editing & commenting | Figma, Adobe XD |

2. 3D Modeling & Structural Layout

Before paper meets press, 3D CAD models show how boxes fold, how inserts hold pocket knives snugly, and where magnetic closures sit. Fold‑flat dielines ensure bleed margins (usually 3 mm) so that cuts leave no white edges.

Tip: A quick virtual turn on the 3D viewer catches structural flaws—no surprises when the first physical mock‑up arrives.

3. Functional & Security Features

Does your knife need anti‑scratch slots? A blister pack must be vacuum‑formed just right to avoid rattles. Anti‑counterfeit holographic seals or invisible UV‑reactive inks add brand protection—and peace of mind.

4. Multilingual Manuals & Inserts

For global toolbox sellers, manuals in English, Chinese, Spanish, French, and Arabic live in the same booklet—carefully laid out to avoid layout shifts when text expands by 30–40%. Live word‑count tracking in Google Docs keeps copy urgent and precise.

5. Client Review & Iterations

Clients leave sticky notes on digital proofs, suggesting tweaks. Shieldon’s average approval cycle drops from 10 days to 5 when using Figma’s plugin ecosystem for annotations.

Rhetorical Question: Ever wished you could tweak a color in real time? With today’s tools, you can.

Sample Production & Confirmation

Before mass production, samples prove the concept—like a dress rehearsal before opening night.

- Prototype Runs:

- Short runs on production line mimic full‑scale processes—offset or digital printing, lamination, die‑cutting.- Shieldon prints small batches on CMYK + 2 spot colors at 175 LPI, ensuring crisp graphics.

- Material & Finish Checks:

- Compare soft‑touch vs. velvet lamination.

- Test PET blister clarity (0.5 mm vs. 0.8 mm) and tinplate sheen. - Functional Testing:

- Magnetic closures open/close 1,000 cycles without wear.

- Knife slots resist scratches during insert/removal.

- Client Sign‑off:

- Physical samples shipped to client HQ in 3 days.

- Feedback logged in Asana or Trello, finalized before tooling.

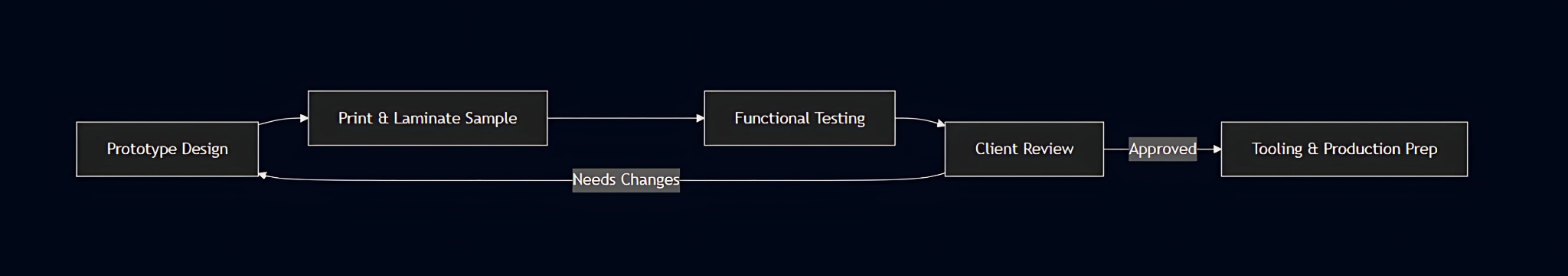

- Illustration: Sample Approval Flow

Example: A multi‑tool blister changed from 0.5 mm to 0.7 mm PET after the client found slight flex—caught in the sample phase, saving thousands in rework.

Material Procurement & Pre‑Treatment (2–3 days)

Sourcing the right eco‑friendly substrates is like picking the perfect ingredients for a gourmet meal—get it right, and the rest of the process tastes smooth; get it wrong, and the whole dish falls flat.

Before ordering thousands of sheets or reels, procurement teams forecast volumes, issue purchase orders, and lock in lead times with vetted suppliers of paper, plastic, and metal components. In the knife‑making world, that often means grey‑back duplex board at 350 g for rigid boxes, art paper with soft‑touch or velvet lamination for premium feel, PET blister film at 0.5 – 0.8 mm thickness, biodegradable PLA inserts, and tinplate at 0.23 mm chrome‑coated for gift‑set tins.

Once materials arrive, they undergo pre‑treatment to ensure optimal adhesion and print quality. Paper boards pass through static‑removal stations and moisture‑control rooms to prevent warping. Plastic sheets are UV‑cured and corona‑treated to improve ink wetting and surface tension. Tinplate boxes receive a light degreasing wash to remove oils, followed by a phosphate rinse to enhance coating adhesion.

Analogy: Treat your substrates like a canvas—if it’s dusty or oily, even the most spectacular paint job will flake off.

Table: Material & Pre‑Treatment Overview

| Material Type | Specification & Supplier Notes | Pre‑Treatment Steps |

| Grey‑back Duplex Board | 350 g, FSC‑certified; acid‑free for longevity | Static removal; moisture conditioning |

| Art Paper (Soft‑Touch) | Velvet lamination; Pantone‑matched coatings | Clean-room handling; antistatic ionization |

| PET Blister Film | 0.5 – 0.8 mm; food‑grade or recycled content | UV curing; corona treatment |

| PLA Inserts | Biodegradable; 100% compostable | Pre‑drying (60 °C x 4 h); dust‑free packaging |

| Tinplate Boxes | 0.23 mm chrome‑coated; FDA‑approved linings | Alkaline degrease; phosphate conversion coating rinse |

Each step in procurement and pre‑treatment lays a foundation for flawless printing, structural integrity, and regulatory compliance—all within 2–3 days to keep production on schedule.

Printing & Surface Treatment (7–10 days)

Printing high‑resolution graphics is like framing a masterpiece: color accuracy and finish define how the customer perceives quality.

First, design files undergo color calibration to translate Pantone spot colors into CMYK or extended gamut profiles for offset printing at 175 LPI. Small‑batch or variable‑data runs use digital presses for quick turnarounds with consistent color across personalized packaging. Offset presses deliver sharp, detailed images for large volumes; digital is ideal for on‑demand custom runs.

After base printing, value‑added treatments bring the package to life. Spot UV applies a slick, glossy coat to logos or imagery, making them pop under retail lights. Cold foil stamping lays down metallic sheens without heat, speeding production and reducing substrate stress. Embossing or debossing adds tactile 3D relief—imagine the raised contours of a knife blade etched into the box surface.

Rhetorical Question: Who doesn’t love running a finger over an embossed logo?

Table: Printing & Finishing Techniques

| Process | Purpose & Effect | Typical Specs & Standards |

| Offset Printing | High‑volume, precise color (CMYK + spot) | 175 LPI; 300 dpi input files |

| Digital Printing | Short‑run, variable data, fast proofing | 1200 × 1200 dpi; no plate setup |

| Spot UV | Glossy highlights on select areas | Clear UV‑cured coating; mask file creation |

| Cold Foil Stamping | Metallic effects without heat | UV‑cured adhesive; foil reel; in‑line application |

| Embossing/Debossing | Raised or recessed 3D textures | 3 – 4 ton pressure; silicone ejection sheets |

Through meticulous printing and finishing over 7–10 days, packaging transforms from blank substrates into attention‑grabbing sales drivers—ready to protect and promote every Shieldon folding knife or multi‑tool with flair.

Processing

After printing and finishing, packaging enters mechanical processing—turning flat sheets and films into ready‑to‑use components. First up is Eurohole punching, where a specialized die punches the familiar “hanging tab” hole so products like knife sets can display on peg hooks. Next, creasing (or scoring) weakens fold lines to create crisp, accurate folds without cracking the board. Then comes blister forming, where heated PVC or PET sheets drape over molds and vacuum sucks them tight, creating custom cavities for each tool or accessory.

Beyond traditional methods, UV/3D printing adds high‑resolution textures or tactile features directly onto substrates in-line, using UV‑curable inks that bond instantly under light. Finally, die‑cutting trims parts to precise shapes—tolerances as tight as ±0.1 mm ensure uniformity across thousands of units. This blend of punches, scores, vacuums, and blades takes 1–2 days, transforming flat printed sheets into structured packaging.

Surface Finishing

With parts cut and folded, surface treatments add protection and flair. Lamination applies an abrasion‑resistant film—anti‑scratch varieties keep artwork pristine through handling and transport. For waterproofing, solventless laminates bond without harsh chemicals, preserving eco‑credentials. Foil stamping then lays down metallic accents—gold, silver, or custom hues—via heated dies that press foil onto the substrate, creating eye‑catching highlights.

To heighten the sensory experience, embossing (raised) and debossing (recessed) techniques press graphene‑patterned dies into the board, adding tactile depth under fingertips. A separate in‑line UV gloss pass can selectively coat areas for contrast, drying in seconds under lamps. Altogether, these finishes reinforce brand quality and draw shopper attention.

Quality Inspection & Functional Testing (3–5 days)

No packaging ships without rigorous checks. Print inspection systems compare scans of proofs to digital masters, flagging deviations in text, color, or barcodes. Dimensional checks use coordinate measuring machines (CMM) to verify fold angles and die‑cut accuracy within ±0.2 mm. In destructive testing, packages undergo drop tests (1.2 m, ISTA 3A standard) and thermal cycling (–20 °C to 60 °C at 90% humidity for 48 h) to simulate real‑world stresses. These tests weed out defects and confirm functionality before assembly.

Cleaning & Anti‑Contamination Sealing (1–2 days)

Clean packaging looks premium and avoids product contamination. In dust‑free workshops, ionizers neutralize static cling and remove airborne particles before boxing. Food‑grade alcohol wipes clean transparent windows, ensuring clarity for display. Finally, completed packs enter vacuum aluminum‑foil pouches with desiccants and VCI anti‑rust chips, sealing out moisture and oxidation during storage and transit.

Assembly & Shaping

Now the parts come together. Gluing and auto‑fold machines assemble boxes, while trained operators hand‑fold complex inserts for multi‑tool kits. Adhesives range from hot‑melt for rapid setting to eco‑friendly water‑based glues. High‑speed folding lines can shape hundreds of units per minute, yet specialty gift sets often require manual finishing for perfect alignment.

Warehousing

Finished packaging waits in climate‑controlled racking, organized by SKU, material, and production date. Just‑in‑time systems trigger picks when the production line scans order numbers, preventing over‑stock and minimizing storage costs. Barcode and RFID flows automate inventory counts, ensuring real‑time visibility of packaging assets.

Delivery

With packaging materials staged seven days before use, logistics partners coordinate timed deliveries to assembly areas. Auto‑matching software links packaging batches to tool orders, reducing errors on busy production floors. Reliable carriers and scheduled routes guarantee on‑time arrival, so Shieldon’s custom knives and outdoor gear always ship in perfect packaging—ready for retail or direct‑to‑consumer fulfillment.

Wrapping Up

From first sketches to final warehouse racking, the Packaging Production Process weaves creativity, engineering, and quality control into every box and blister pack. By following each step—analysis, design, sampling, procurement, printing, processing, finishing, inspection, cleaning, assembly, warehousing, and delivery—Shieldon ensures that every folding knife, multi‑functional tool, and outdoor gadget arrives safe, compliant, and unforgettable. Partnering with professional manufacturers like Shieldon means a seamless journey from concept to customer, every time.