Shieldon offers a clear and efficient product development process to bring ideas to life. Starting with a confidentiality agreement, each stage is carefully managed to ensure quality and meet client requirements.

The process begins by confirming product needs like functionality, materials, and certifications. Detailed design and engineering follow, including 3D modeling, material selection, and prototype testing.

Once approved, mold manufacturing and small batch production verify specifications before mass production.

Shieldon keeps communication open, providing regular updates and promptly addressing concerns. Packaging design and product cleaning are handled carefully to ensure the final product arrives in perfect condition.

With a strong focus on quality control and transparency, Shieldon delivers products that meet expectations and exceed industry standards.

Workflow Mapping: Steps Shieldon Does for Perfect OEM Process

1. Confidentiality Agreement Signing

Before any product development begins, Shieldon requires both parties to sign a Non-Disclosure Agreement (NDA).

This agreement ensures that all sensitive product data, including design drawings, mold blueprints, and production process parameters, remain confidential.

The NDA serves as a foundation of trust between the two parties, protecting the integrity of the product development process and preventing the leak of critical information to third parties.

2. Requirements Confirmation (5-7 Days)

Once the NDA is in place, Shieldon works with the client to confirm the product’s requirements within 5-7 days. This includes confirming specific parameters such as dimensions, materials for the blade and handle, color options, accessories, edge curvature, and packaging details.

In addition, Shieldon clarifies regulatory requirements for the target market, including certifications like EU CE and US knife control regulations, as well as environmental compliance standards like ROHS. If the client provides reference samples, these are disassembled and analyzed to ensure key parameters are met. The engineering team also assesses potential production challenges and provides early feedback on risks to ensure smooth development.

3. Design and Engineering Development (7-10 Days)

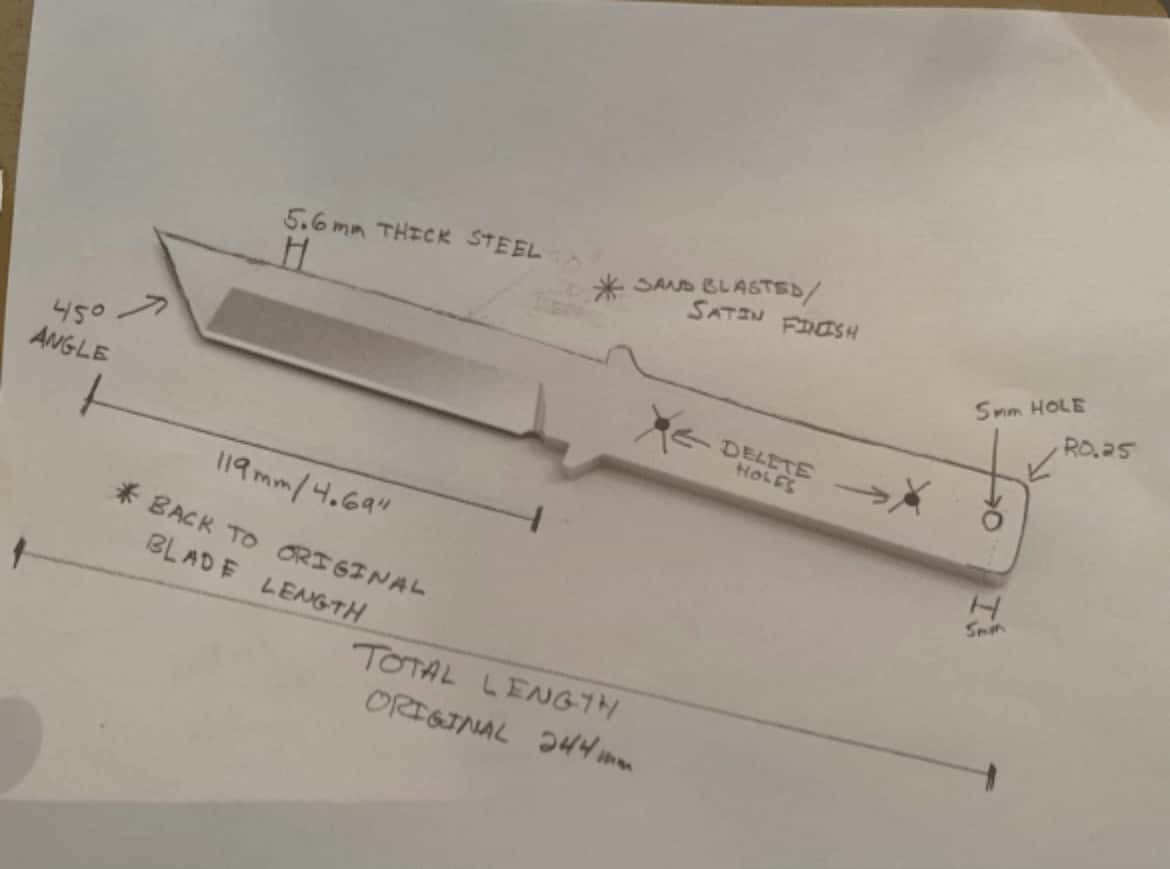

The next step is design and engineering development, which typically takes 7-10 days. Shieldon creates preliminary structural dimension drawings and 3D renderings based on the confirmed product parameters for the client’s approval.

Using advanced CAD software, the designs are modeled and subjected to simulation testing to verify their structural integrity.

Material options are carefully selected, with test reports on hardness, corrosion resistance, and compliance with conflict mineral regulations provided. If custom parts are needed, the sharing of mold costs is clarified, including details on upfront payments and mold plan confirmation.

4. Quotation (3-4 Days)

Once the design and engineering phase is complete, Shieldon prepares a detailed quotation based on the confirmed specifications. This quotation, which takes 3-4 days to provide, includes mold fees, sampling, mass production, packaging, and certification costs.

Shieldon outlines payment terms, typically requiring a 30-50% deposit and the balance to be paid before shipment.

The terms also include clarity on liabilities for delays or substandard quality, ensuring transparency throughout the process. An exchange rate fluctuation clause is included to protect both parties from currency risks, ensuring that payments are settled at the exchange rate on the payment date for long-term projects.

5. Sample Production (4 Days + 6 Days Shipping)

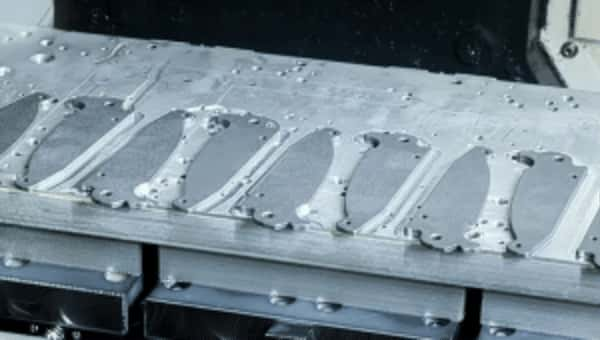

Sample production begins with the creation of 3D printed plastic samples, which allow the client to evaluate the appearance, dimensions, and primary functions of the product.

This initial sample provides an opportunity for any immediate modifications to be discussed. In addition to 3D resin printed samples, CNC metal prototypes are produced to test critical features such as the smoothness of the blade’s opening and closing mechanisms, and the strength of the locking mechanism.

These functional testing samples ensure that the product performs as intended before moving to full production.

6. Mold Manufacturing (Approximately 30 Days)

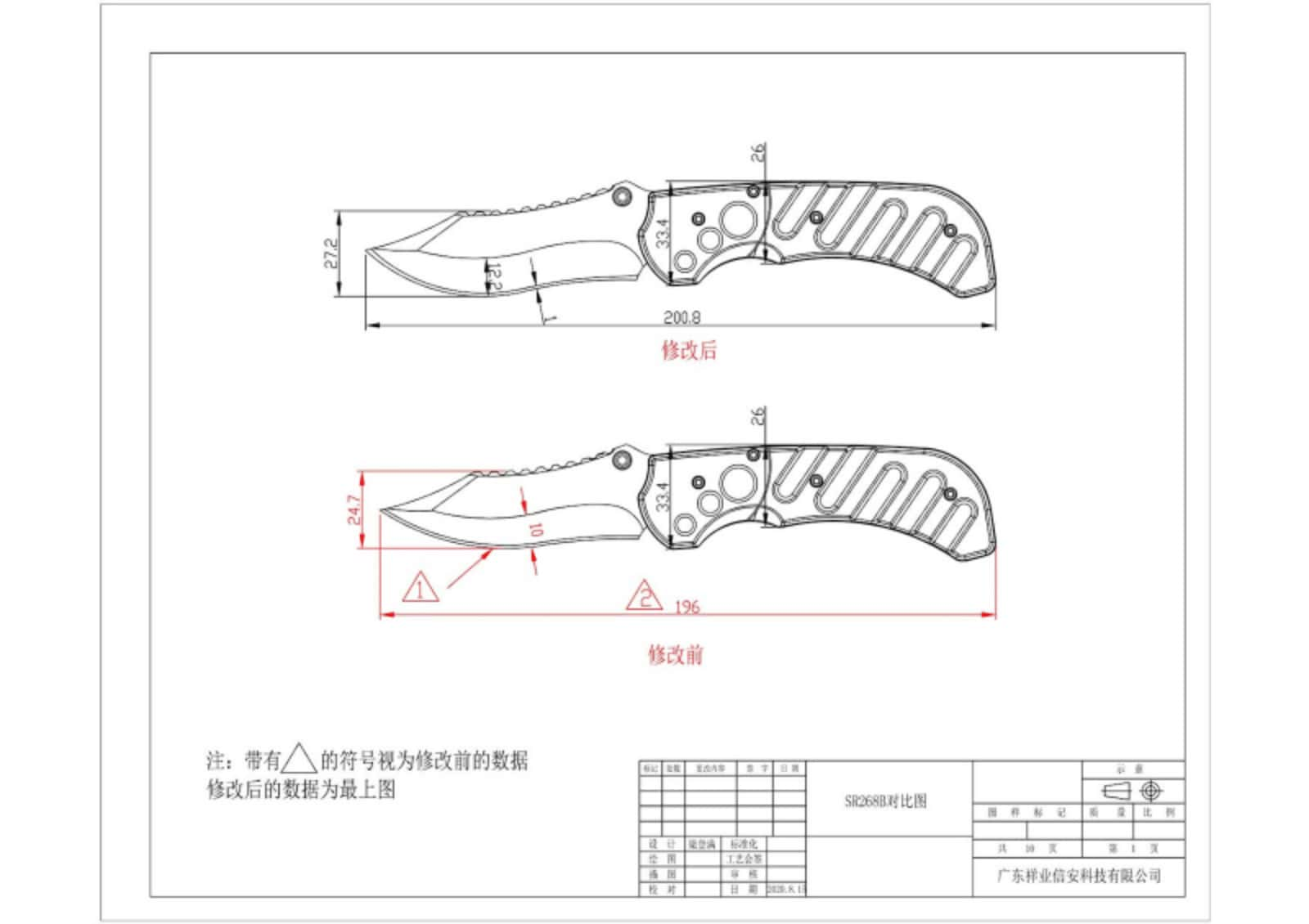

Mold manufacturing typically takes around 30 days and begins with the T0 trial molding stage, where initial mold testing is conducted.

Any issues, such as flash or shrinkage, are identified, and mold parameters are adjusted accordingly. In the T1 trial molding stage, components closely resemble the finished product, allowing for full dimensional inspection (e.g., blade thickness tolerance).

The T2 trial molding stage involves small-scale production (50-100 pieces) to verify mold stability and ensure compatibility with production lines. Once the mold is suitable, the client signs the Mold Acceptance Confirmation, allowing mass production to proceed.

7. Production of Functional Prototypes (30 Days + 6 Days Shipping)

Once the mold is finalized, functional prototype production begins. These prototypes are created based on the last confirmed product parameters and shipped to the client for testing and marketing purposes.

Shieldon provides a Prototype Testing Report Template to help the client offer feedback on important features like blade sharpness and grip comfort.

If any design adjustments are needed, such as adding anti-slip textures or optimizing bearing structures, these are made based on the feedback.

The client confirms the samples through a Sample Approval Agreement, which sets the standards for mass production. The client can submit the prototypes to a third-party testing facility (e.g., TÜV Germany) to enhance market credibility if necessary.

8. Mass Production (Approximately 90 Days)

Mass production takes approximately 90 days, during which Shieldon ensures continuous transparency in the production process.

Regular updates, including images or videos, are provided to inform the client.

Quality inspections are conducted at various stages, such as the First Article Inspection (FAI), where the first batch of 50 pieces is fully inspected and compared against sample data.

Statistical Process Control (SPC) is implemented to monitor key production parameters, and segmented quality inspections are conducted weekly to check the appearance and functionality of semi-finished products.

The production environment, including temperature and humidity standards, is carefully controlled to ensure optimal conditions, especially in areas prone to rust. Third-party inspections conducted by organizations like SGS or those designated by the client, can be arranged if required.

9. Packaging Design (14 Days)

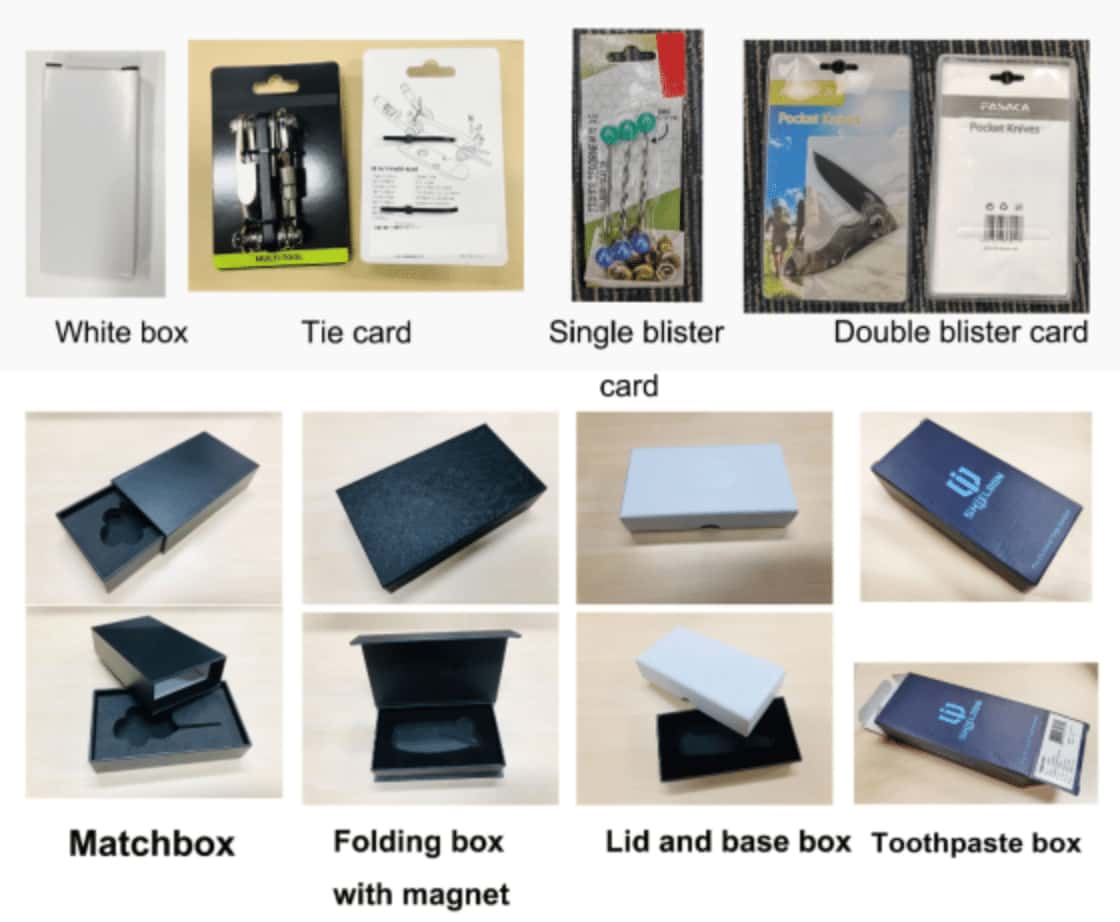

If the client requires packaging material design during production, Shieldon provides free flat design drawings.

This packaging design is synchronized with mass production to ensure a streamlined process, saving approximately 14 days. To ensure the packaging’s effectiveness, ISTA transport testing simulates transport vibrations and drops to assess its protective performance, especially for products with easily detachable components.

Environmental labels, such as recyclable material labels (e.g., FSC-certified paper), are included to promote sustainability in packaging.

10. Packaging Printing (50 Days)

Once the packaging design is confirmed, Shieldon proceeds to print packaging boxes, cards, and instruction manuals, or procures the necessary packaging materials externally.

This phase generally takes around 50 days and ensures that all printed materials meet the agreed-upon design specifications, helping to present the product in its final, ready-to-ship form.

11. Final Product Cleaning (10 Days)

Before packaging, the products are cleaned to ensure they meet the client’s quality standards. Shieldon then packages the products according to client specifications and boxes them for shipment.

A traceability system is implemented where each box is labeled with a unique traceability code, which includes the production date and batch number.

This code supports quality inspection record tracking and ensures that any quality concerns can be traced back to specific production batches.

12. Pre-shipment

Before shipment, Shieldon retains 3-5 samples from each batch for archival purposes. These samples can be referenced in case of any quality disputes or concerns.

Additionally, to prevent rust on knives during maritime transport, Shieldon offers logistics temperature and humidity monitoring solutions, such as providing desiccants in shipping containers.

This ensures the products remain in optimal condition throughout the shipping process.

13. Shipment (14-35 Days)

Once everything is packed and ready, the final payment is submitted, and the shipment proceeds according to the client’s requirements and the agreed trade terms in the contract. Shieldon can also assist with customs clearance at the destination country if needed.

To ensure smooth international shipping and customs procedures, a complete set of export compliance documents, including a packing list, Certificate of Origin, and material declaration accompany all shipments.

Takeaways

Shieldon’s OEM customization process is built to make life easier for clients in the knives and tools industry.

Each stage is tailored to meet your needs and industry regulations. Using advanced tech like CAD modeling and simulations, Shieldon enhances product quality while keeping you in the loop with regular updates and clear communication because trust matters.

Feedback is gathered at every step, from prototypes to final tests, ensuring the final product meets and exceeds your expectations.

Shieldon doesn’t just deliver products; they build lasting partnerships by focusing on quality, customer satisfaction, and solutions that fit your business perfectly.