Tempo de espera

O Shieldon historical project received a prestigious annual award. This project lasted from September 2021 to December 2022, highlighting its remarkable duration. It was a collaborative effort, with Shieldon and the customer each contributing 50% to the design process.

This joint quest included design, prototyping, redesigning, and eventually transitioning to mass production. The team worked tirelessly to improve the product, resulting in a successful completion after over a year of dedicated effort.

Como surgiu o projeto

The customer compared 2-3 manufacturers before choosing Shieldon. Despite having an incomplete design, the customer needed assistance in several areas. While everyone wants flawless designs, not everyone knows how to seek help or if the manufacturer is willing to refine the design before production.

True to our word, Shieldon is dedicated to assisting customers in enhancing their designs, as we craft facas e ferramentas with utmost dedication. After careful consideration, the customer decided to collaborate with the Shieldon team.

Reasons why customer chose us

We supplied exploration images with pricing on each component

To ensure clarity, we meticulously separated each component and individually priced the molding sets. Recognizing that the customer had reached out to multiple suppliers for pricing, we intended to save their valuable time.

By transparently providing pricing for each moulding set, we aimed to help the customer comprehend the overall cost. Our sincerity touched the customer, as they now had a clear understanding to effectively evaluate their design.

We supplied packaging

The customer’s new brand lacked any packaging concept, let alone a package box. We presented various popular box designs for selection, and ultimately, the clamshell box became the customer’s top choice.

We assisted in creating a prototype of the box and even designed the sticker. The customer was highly pleased with our printing service.

In addition to our exceptional metal production capabilities, they also commended our expertise in packaging design and printing.

We supplied different steel finishes for comparison

As mentioned earlier, the customer still had a few things to consider and wasn’t quite sure how to proceed. For example, they were thinking about the best type of steel for the skateboard tool and ways to make it look even better.

They also wanted to improve the quality without breaking the bank. We knew it was important to have detailed discussions to fully understand the customer’s needs, which is why the project took some time.

At Shieldon, we made it a point to address each of the customer’s concerns individually. With every conversation and suggestion, the customer’s trust in us grew. This created a friendly and seamless communication environment.

História do Processo de Fabricação

1). The objective was to create a multi-functional tool with various components. We started by printing a 3D prototype based on the client’s design. While the prototype revealed some inconsistencies, we adjusted the design and printed another one. Once we had a satisfactory 3D model, we consulted the client about the necessary changes and then proceeded to create a steel prototype.

2). The second image shows the prototype made from actual steel. The purpose was to ensure all parts were perfect before moving on to the next phase. Unlike a high-end faca dobrável, a multi-tool requires creating molding sets before component production – a process that is time-consuming and costly. If the mold sets were incorrect, the subsequent components would also be flawed.

3). After polishing the handle scales, we assembled the prototype to verify functionality. At this point, the steel prototype was almost complete. We scrutinized each part, determining areas of potential improvement and discussing them with the client.

Maintaining clear communication was crucial, even though the path was challenging given the distance and cultural differences between us.

4). We delved deep into the intricate details of the tool, examining every aspect. For instance, we showcased two distinct finishes for the handle – a sleek grey and an elegant black titanium coating.

We provided the customer with comprehensive information about these options and introduced a touch of innovation by suggesting a hexagonal pattern, which was absent from the client’s initial concept.

Our focus extended beyond aesthetics; we also meticulously tested the blade’s sharpness and evaluated the hexagon’s practicality. Once we were satisfied with the results, we finalized all the details and proceeded with the creation of the moulding set, paving the way for production. This comprehensive process spanned approximately four months.

5). After a month, the pre-production sample was ready. Aptly named a “Skateboarding Tool”, it was a multi-functional tool aimed at aiding skateboard enthusiasts in maintaining their boards. With seven features packed into a single tool, this was a result of meticulous planning and execution.

We used 3Cr for the blade, common stainless steel for the body and 304 stainless steel for the screws and minor parts. The tool may appear simple, but every effort was focused on enhancing its quality and utility based on the customer’s original design.

6). We walked the customer through the making of each part and explained the technique used in the simplest terms possible. Despite the extensive production process, we ensured the customer understood the final result.

7). In the pre-production sample, we noticed some differences, which is pretty normal when a design goes from a CAD file to a physical product.

We had to make these adjustments to match the manufacturing techniques. We made sure to explain these changes to the customer in detail, so they understood how hardware production works.

8). The next image shows how we had to trim a portion of the metal to ensure the component was manufactured. A testament to our commitment to practical and effective design solutions.

9). Then we shifted our attention to an add-on for the skateboarding tool – a detachable hexagon. This hexagon, although it looks simple, was specifically designed to flawlessly fix hex screws.

The initial version didn’t quite match the tool, so we made some adjustments to ensure a perfect fit, showing Shieldon’s commitment to constant improvement. And of course, we kept our customers in the loop about these upgrades, boosting their confidence in our partnership.

10). To facilitate easy self-repairs, we suggested including a small screwdriver with interchangeable T6 and T8 heads in the package. The customer appreciated our thoughtful consideration and approved this addition promptly.

11). The packaging design presented an intriguing challenge as the customer struggled to envision a specific concept.

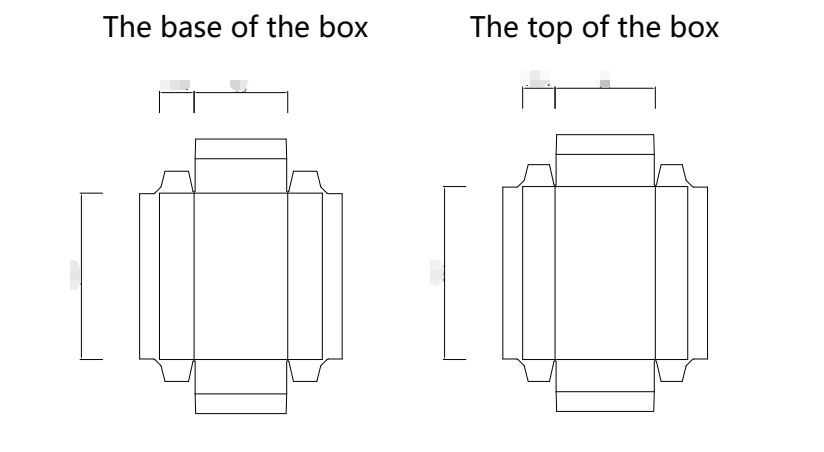

Our team devised two compelling options: a sleek one-side-open clamshell box with a magnetic lock, and a sophisticated top-and-base box reminiscent of iPhone packaging. While we leaned towards the elegant simplicity of the iPhone-like box, the client ultimately opted for the allure of the clamshell design.

12). We created renderings of the packaging, incorporating the customer’s brand name and

slogan. The chosen design was a cool, mysterious black box. Once the design and appearance were finalized, we partnered with a printing factory to bring these boxes to life.

13). During the final production phase of the skateboard tool, we kept in touch with our customers every step of the way. We made sure to keep them updated with regular progress reports and photos. As we neared the finish line, after ten months of hard work, we stayed committed to our goal.

14). Next, we had to do a test run of the packaging, you know, fitting the product into the box to make sure it fits just right. We wanted to take into account things like marketing and transportation, so we spent some time making sure that the EVA tray inside the box would keep the tool safe and sound during shipping. Our goal is that moment when the customer opens the package and is instantly drawn to our amazing product.

15). As the production neared completion, we introduced two color variations on the handle – silver titanium and rainbow titanium. The titanium coating not only enhanced the look of the tool but also protected the steel from rust.

The packaging was meticulously planned, with shrink film and an EVA plate enclosing the tool. This method ensured the tool’s protection and gave it a more elite appearance. We did face minor challenges, but we were determined to overcome them before the shipment.

16). Fast forward to a year later, what was a mere CAD file concept had turned into a tangible product. The product’s transformation from an abstract idea to a physical object was a testament to our labor of love and dedication towards this project.

We were proud of what we achieved, and we encouraged feedback from our customers. Our workshop peers were so fascinated by the final product that they each wanted a piece for their collection.

17). The images illustrate both the top and bottom view of the box. The brand logo and slogan underwent several alterations before the final version was approved. This process is quite typical, as aesthetics can be subjective. However, one principle the Shieldon team and the customer agreed on was simplicity being the hallmark of good design.

18). The customer requested to include a special sticker within the box, a practice common in the outdoor knives and tools. Brands often include items like velcro, brooch, plush, or lanyard as a complimentary gift, creating a unique culture around such products. Shieldon is well versed in this tradition, having fulfilled similar requirements for many of its customers.

Remessa e Resumo

1). Over 12 months, our skateboard tool, initially conceived as a simple CAD design, truly came alive. Now available in three vibrant color options, it stands out as a distinctive highlight among our range of custom multi-tools crafted in 2021.

Before shipping, rigorous quality and functionality tests were conducted to ensure the delivery of a superior product. More than just an item, this tool embodies our unwavering commitment to embracing challenges and crafting unparalleled creations within our industry.

2). Here’s a closer look at the tool. To prevent humidity damage, we include a silicon gel with every tool. Nestled in a plush EVA tray, the tool transforms into a premium product – a must-have for all skateboarding enthusiasts.

3). For shipping, we adhere to standard rules, packing 20 boxes in 1 carton. This makes transportation and customs clearance easier. With the project almost complete after nearly a year, seeing it ready for dispatch is a rewarding moment.

4). This project has enriched us with invaluable experience, not just in design and production, but also in terms of international communication. Establishing global business relations can be tough, but the reward is seeing our quality products reach skateboarding enthusiasts worldwide.

We eagerly anticipate hearing about the tool’s sales performance from our customers, but we’re confident it’ll be a hit. Here’s to a successful 2023 for the best-selling skateboard tool!

5). Take a look at the final product crafted by Shieldon. If you’re interested in learning more, reach out to our team. We’re excited to hear your ideas for new knives and tools. See you next time!

And don’t forget, you can explore more Shieldon creations on our social media: