The Production Process of a Folding Knife

Making a high-quality folding knife is no simple task. It’s a meticulous process that involves precision, skill, and advanced technology at every step. From crafting the blade and handle to assembling the final product, every detail matters to ensure durability, functionality, and safety. Whether you’re curious about the craftsmanship behind folding knives or want to understand how […]

Packaging Production Process

Every great product needs great packaging. The Packaging Production Process shapes how your pocket knives, multi‑functional tools, and outdoor gear arrive safely—and look irresistible—on store shelves and doorsteps. At Shieldon, leading custom tool manufacturers and wholesale knives suppliers, we know that a seamless packaging journey turns first impressions into loyal customers. In this article, we’ll walk […]

Multi-tool Manufacturing Process

Imagine a craftsman shaping metal and composite, one stroke at a time, forging a versatile multi-tool that fits in your pocket. The multi-tool manufacturing process brings together materials science, precision engineering, and cutting-edge inspection methods to create a reliable everyday companion. From selecting aerospace-grade alloys to laser-assisted positioning during final assembly, every step ensures performance and […]

OBM Brand Distribution

At Shieldon, we believe that knife quality means life. With countless years of experience, we don’t just make knives, we craft reliable everyday carry tools that meet the highest international standards. We know the market changes fast, so we stay ahead by combining the latest manufacturing techniques with deep technical knowledge. If you want to […]

A Comprehensive Guide to the Product Development Process at Shieldon

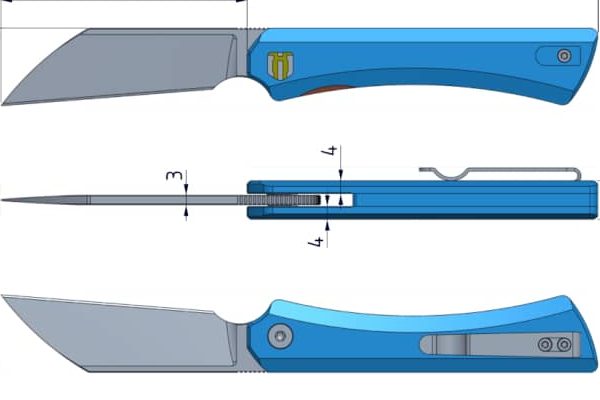

Shieldon offers a clear and efficient product development process to bring ideas to life. Starting with a confidentiality agreement, each stage is carefully managed to ensure quality and meet client requirements. The process begins by confirming product needs like functionality, materials, and certifications. Detailed design and engineering follow, including 3D modeling, material selection, and prototype […]

Revelando a obra-prima: testemunhe a criação hipnotizante do MP01 Blacksmith Rain

História do procedimento de fabricação do ferreiro Mp01 Rain Michael Pretsch e o nascimento de Rain – a icônica faca EDC de Shieldon” Em um reino onde as facas são mais do que apenas ferramentas, surgiu um designer carismático chamado Michael Pretsch. Nos últimos cinco anos, ele mergulhou na arte do design de facas, elaborando […]

O processo de design abrangente da faca Blacksmith Hierophant MS01A

A faca Blacksmith Hierophant MS01A é um produto único e inovador, projetado e trabalhado com a máxima atenção aos detalhes por Matthew Szymanski e Shieldon. O processo de design foi abrangente e incorporou tanto técnicas tradicionais quanto princípios modernos de engenharia. Desde a seleção de materiais até o teste final e polimento, cada etapa […]

Processo de Shieldon e Eric Garza para fazer a faca Blacksmith Viper EG01A

Como usuários e fabricantes profissionais de facas, Shieldon e Eric Garza entendem a importância de ter uma faca de qualidade. Os usuários de facas precisam de facas que possam lidar com qualquer situação, enquanto os fabricantes de facas precisam de facas que possam ser submetidas a testes rigorosos sem falhas. É por isso que eles se uniram para criar o Blacksmith Viper […]