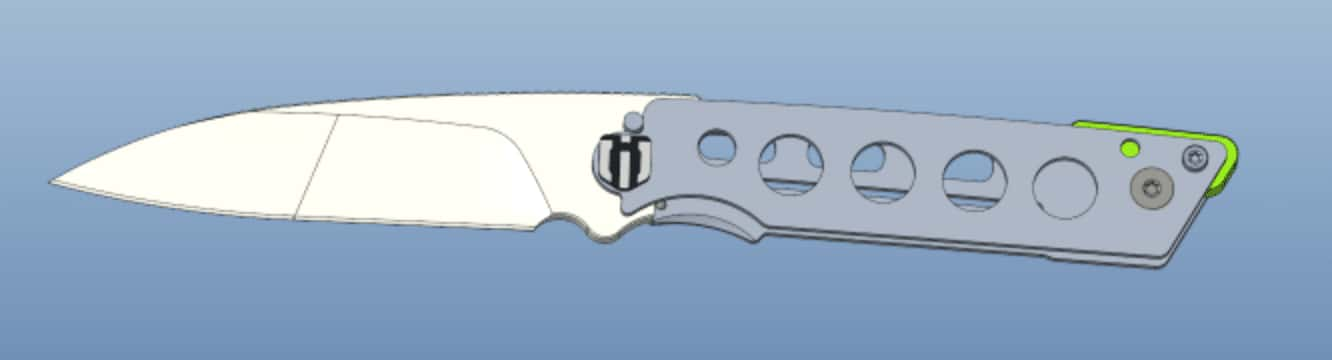

Le Stinger Folding Knife, designed by Marcus Williamson (USA), is a high-quality everyday carry (EDC) knife that combines durability, precision, and ease of use.

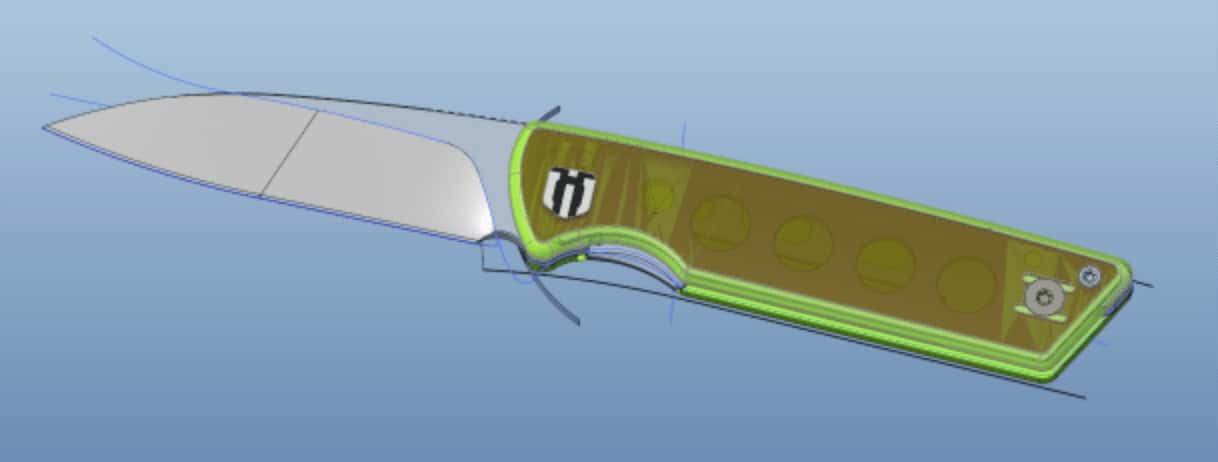

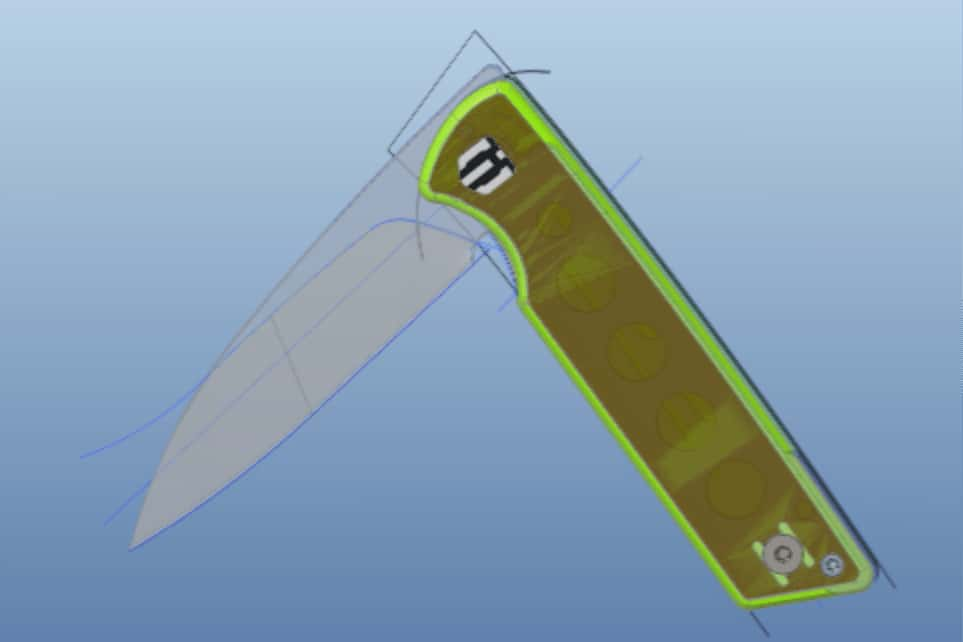

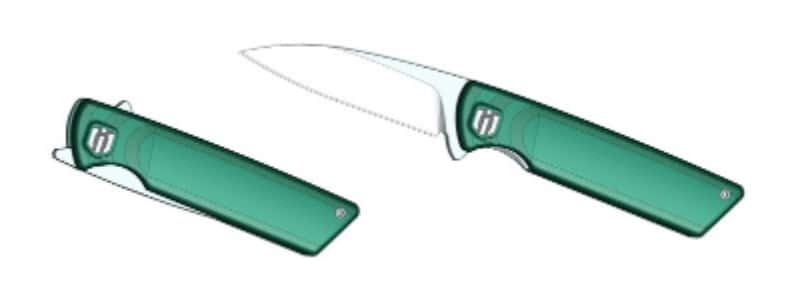

Inspired by a strong fixed-blade design, the Stinger has been transformed into a portable and slim folding knife, making it perfect for daily tasks.

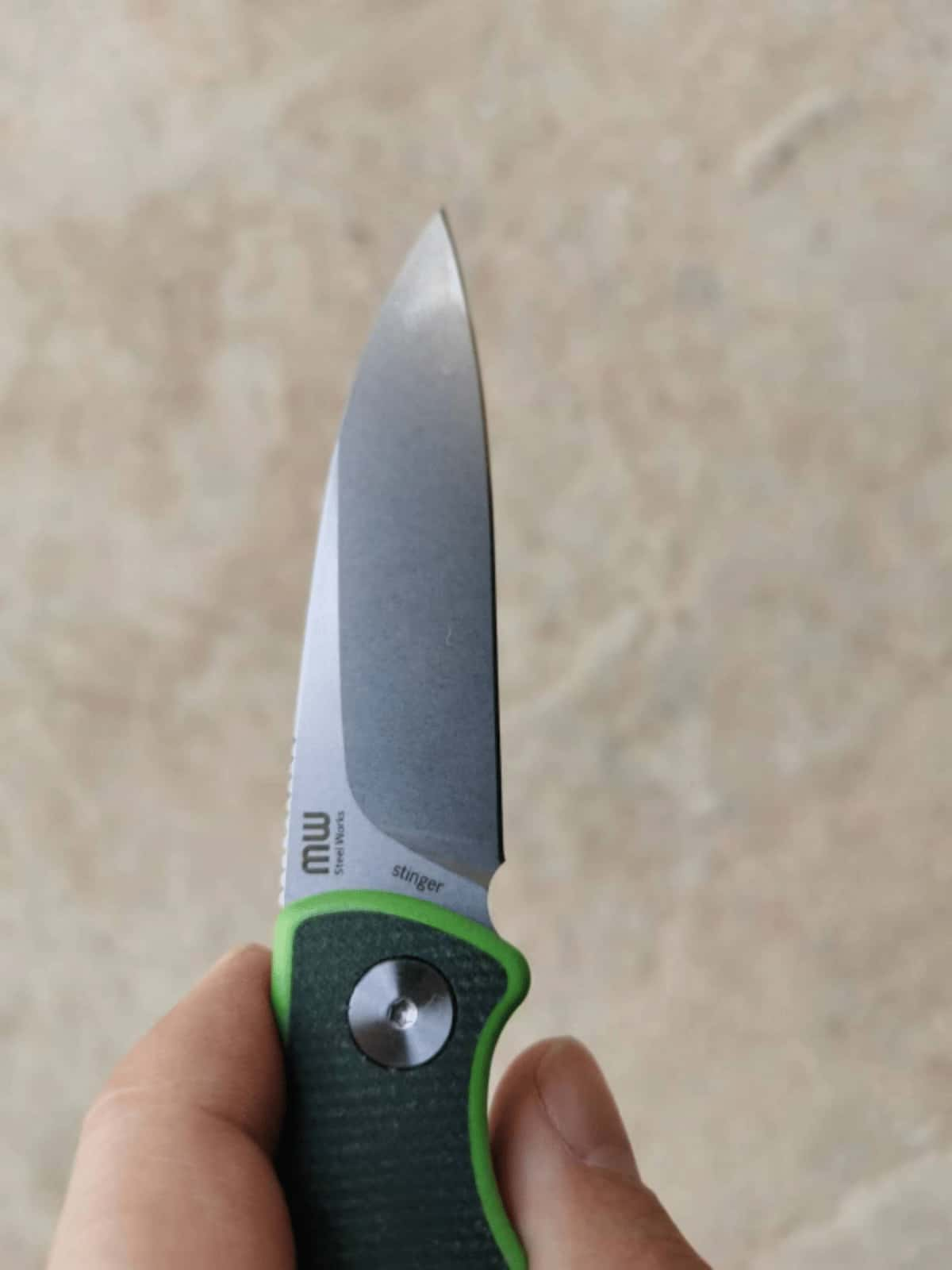

The blade is made from 14C28N steel, a budget-friendly but high-end material known for its sharpness and edge retention.

The drop-point shape improves control and safety, while the stonewash finish helps reduce glare and hides scratches.

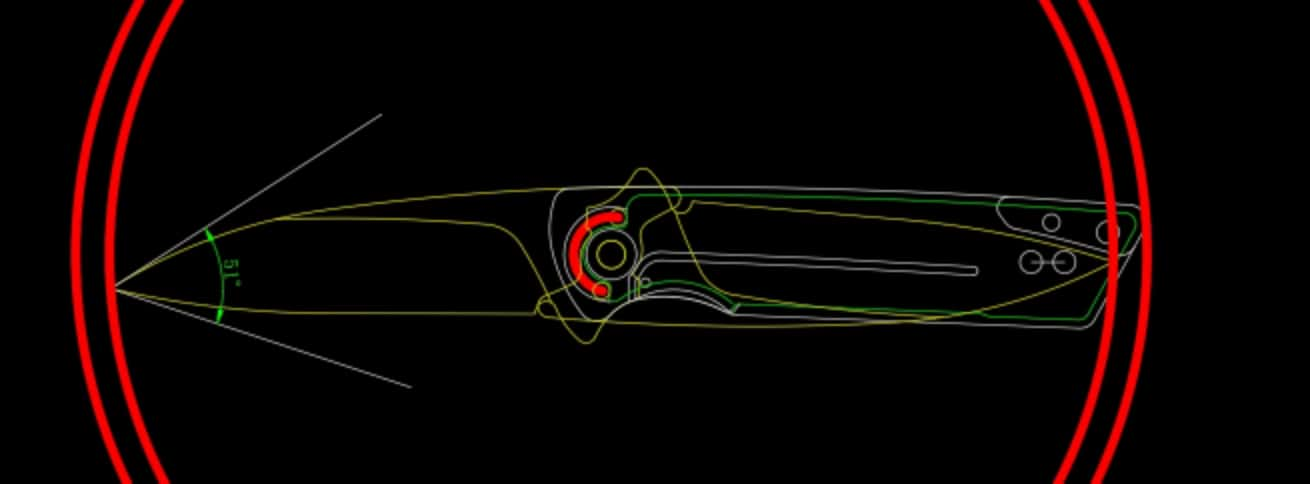

The 15-20 degree sharpening angle perfectly balances sharpness and durability.

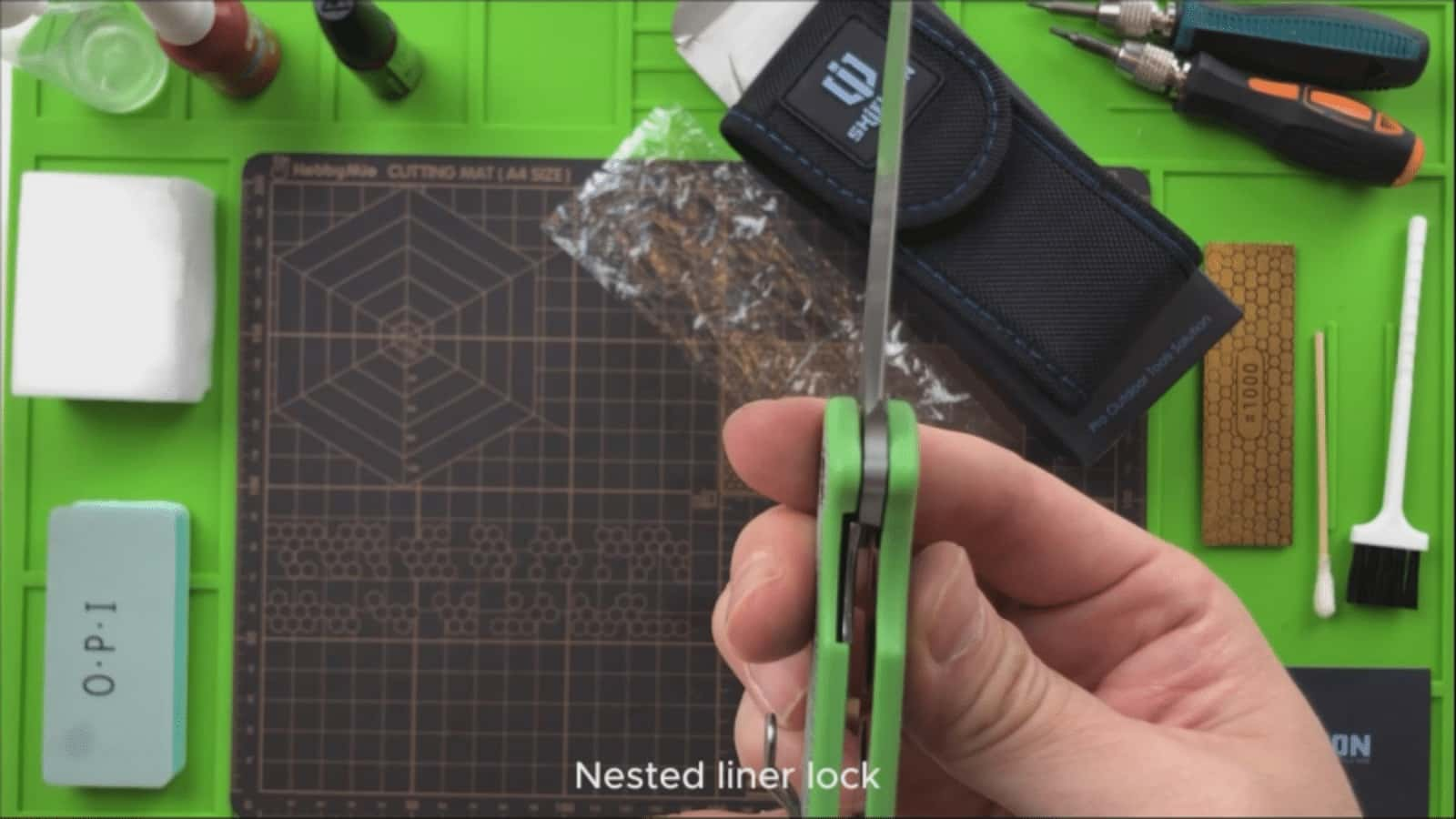

The lawngreen G10 handle with an olive micarta inlay offers a secure grip and moisture resistance, making it reliable in various conditions. The nested liner lock provides extra strength and safety, while T8 screws allow for easy maintenance.

The reversible pocket clip supports left- and right-handed users for added convenience. The caged ceramic ball bearing system ensures smooth and fast blade deployment.

Weighing only 2.68 oz (76g), the Stinger is a lightweight, durable, and easy-to-carry knife, making it an excellent choice for anyone needing a dependable EDC tool.

Concept Value of Stinger Folding Knife: What Makes It Unique?

The Stinger Folding Knife transforms a popular outdoor fixed-blade design into a compact and practical everyday carry (EDC) tool while maintaining its original style.

Designed by Marcus Williamson (USA), this knife reflects his craftsmanship and passion for quality blades.

By expanding into the folding knife market, the designer aims to reach a broader audience and collaborate with different brands.

The lawn green G10 handle, with an olive micarta inlay, provides a comfortable grip and introduces a fresh and unique color combination.

This design choice supports the advocacy for eco-friendliness, encouraging users to appreciate and care for the environment.

With its durable materials, smooth deployment system, and ergonomic design, the Stinger is a versatile, stylish, and functional EDC knife for everyday tasks.

Designer Procedure: How Did Stinger Folding Knife Came to Life?

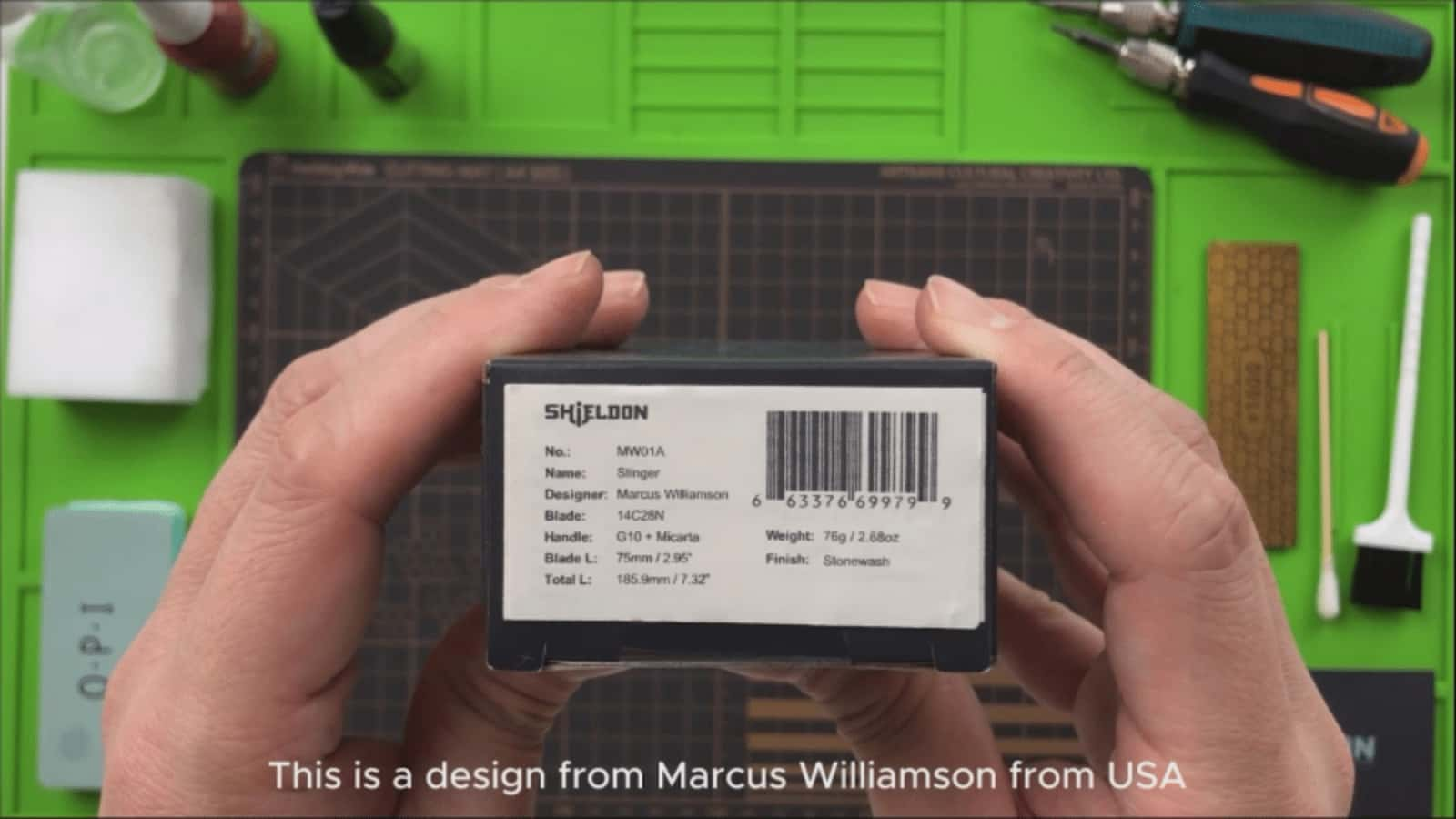

- Innovation and collaboration shape the knife industry. Shieldon Knives worked with Marcus Williamson (USA) to transform his best-selling outdoor fixed-blade knife into a compact everyday carry (EDC) folding knife. This process combined expertise, design discussions, and a shared vision to create a new product.

- Marcus Williamson, known for his high-quality knife designs, offered to sell the copyright of two best-selling outdoor knives. However, he required his designer IP to be prominently featured. Shieldon Knives recognized the potential and agreed to move forward.

- After market analysis, Shieldon Knives focused on one fixed-blade model, aiming to adapt it into an EDC folding knife. Marcus was initially hesitant but, after multiple discussions, saw the value in the redesign.

- This project was more than just a business collaboration. It was a fusion of ideas between a manufacturer and designer, leading to a unique and innovative product.

- Fixed-blade knives are durable and reliable but require a sheath for carry. Their single-piece construction makes them ideal for heavy-duty tasks but less convenient for everyday use.

- Folding knives, like the Stinger, offer portability and safe storage. They require a locking mechanism and a well-designed handle to ensure usability and comfort.

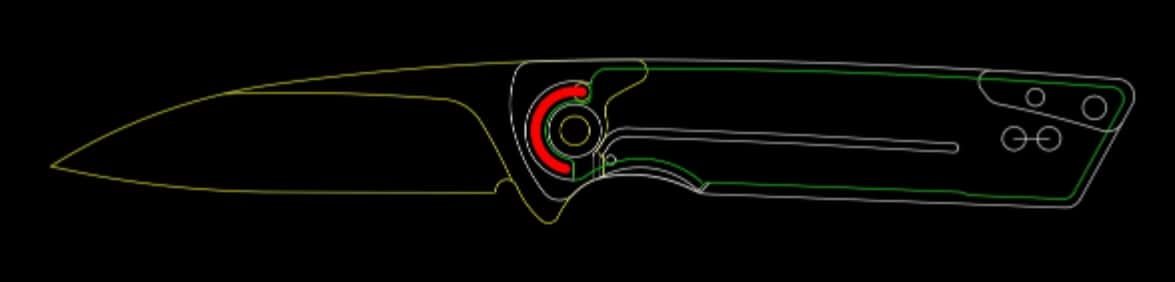

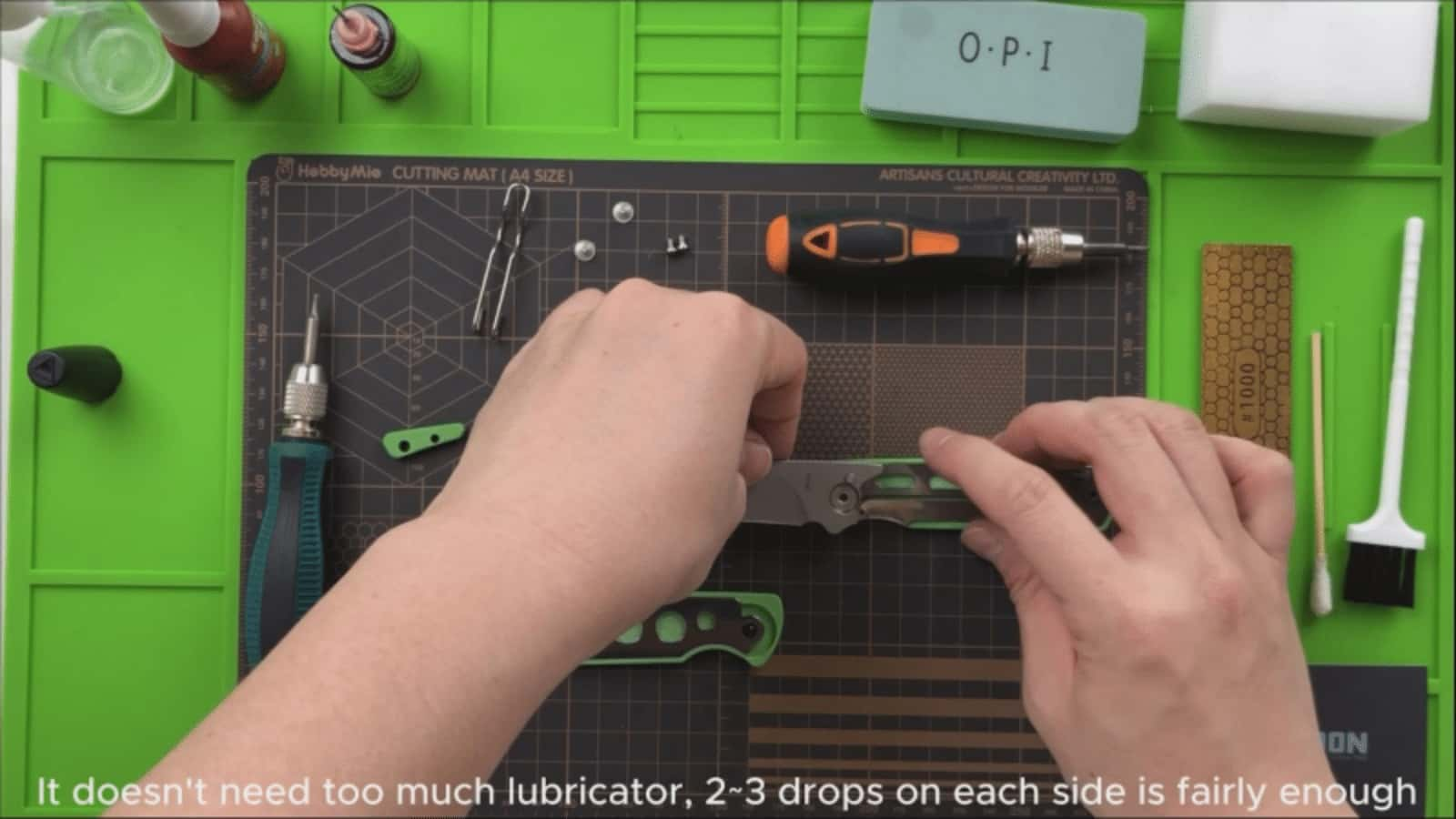

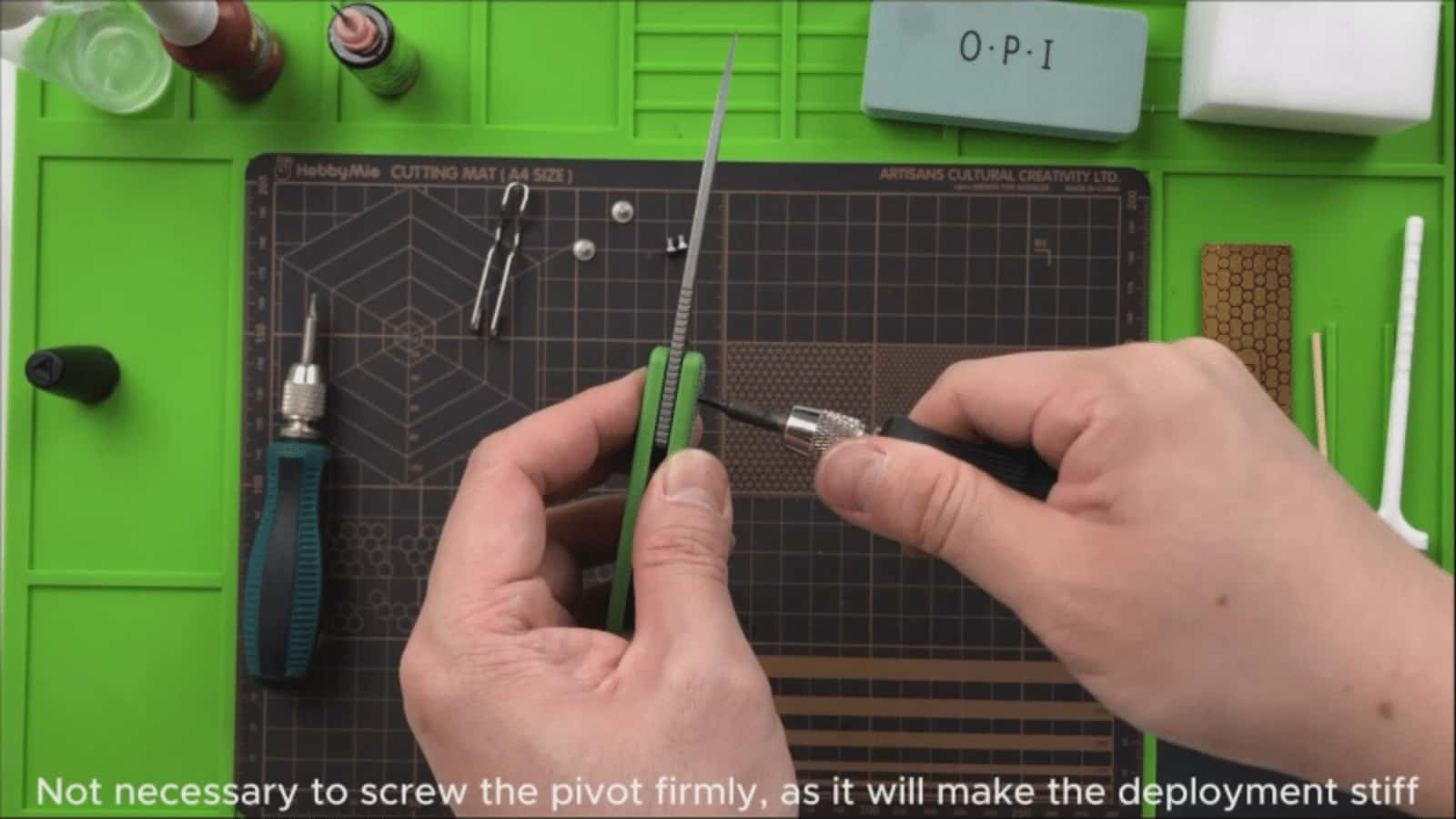

- The pivot system was crucial to achieving smooth blade deployment. Precision engineering ensured durability and consistent performance.

- Marcus emphasized eco-friendly materials, choosing a lawngreen G10 handle with an olive Micarta inlay to support sustainability and create a visually striking design.

- Engineers redesigned the nested liners to provide a sturdy folding mechanism while maintaining a slim profile.

- The choice of steel was debated. While Marcus preferred 154CM steel, Shieldon Knives opted for 14C28N steel, balancing performance and affordability.

- The G10 handle and Micarta inlay were shaped for ergonomic comfort, ensuring a secure and stylish grip.

- The blade was redesigned from a fixed to a folding format, maintaining its effectiveness for both outdoor and urban use.

- Final assembly involved precise craftsmanship, ensuring smooth operation. Marcus’s designer IP was applied as a symbol of collaboration.

- After prototyping, the final design was approved. The Stinger Folding Knife successfully blended outdoor toughness with EDC practicality, ready to be introduced to the world.

What are the Best Selling Points of Stinger Folding Knife?

- The Shieldon Stinger combines innovation, practicality, and style in a slim, portable folding knife. Designed for versatility and reliability, it meets the needs of everyday carry (EDC) users and knife enthusiasts.

- The packaging features a distinctive brand color box, reflecting Shieldon’s high standards. Inside, the knife is secured in a nylon pouch, providing both protection and convenience.

- A label inside the box details key specifications, including the model number MW01A, designer Marcus Williamson (USA), 14C28N blade steel, and a G10 handle with Micarta inlay. The stonewash blade finish enhances durability and aesthetics.

- Unboxing the Stinger reveals its solid construction and attention to detail. The handle immediately conveys quality craftsmanship and a comfortable grip.

- The nylon pouch adds an extra layer of protection and serves as a practical carrying case.

- Removing the Stinger from its pouch highlights its sturdy build and precision engineering.

- The lawngreen G10 handle with an olive Micarta inlay provides durability, moisture resistance, and a secure grip. The eco-conscious color choice reinforces a commitment to sustainability.

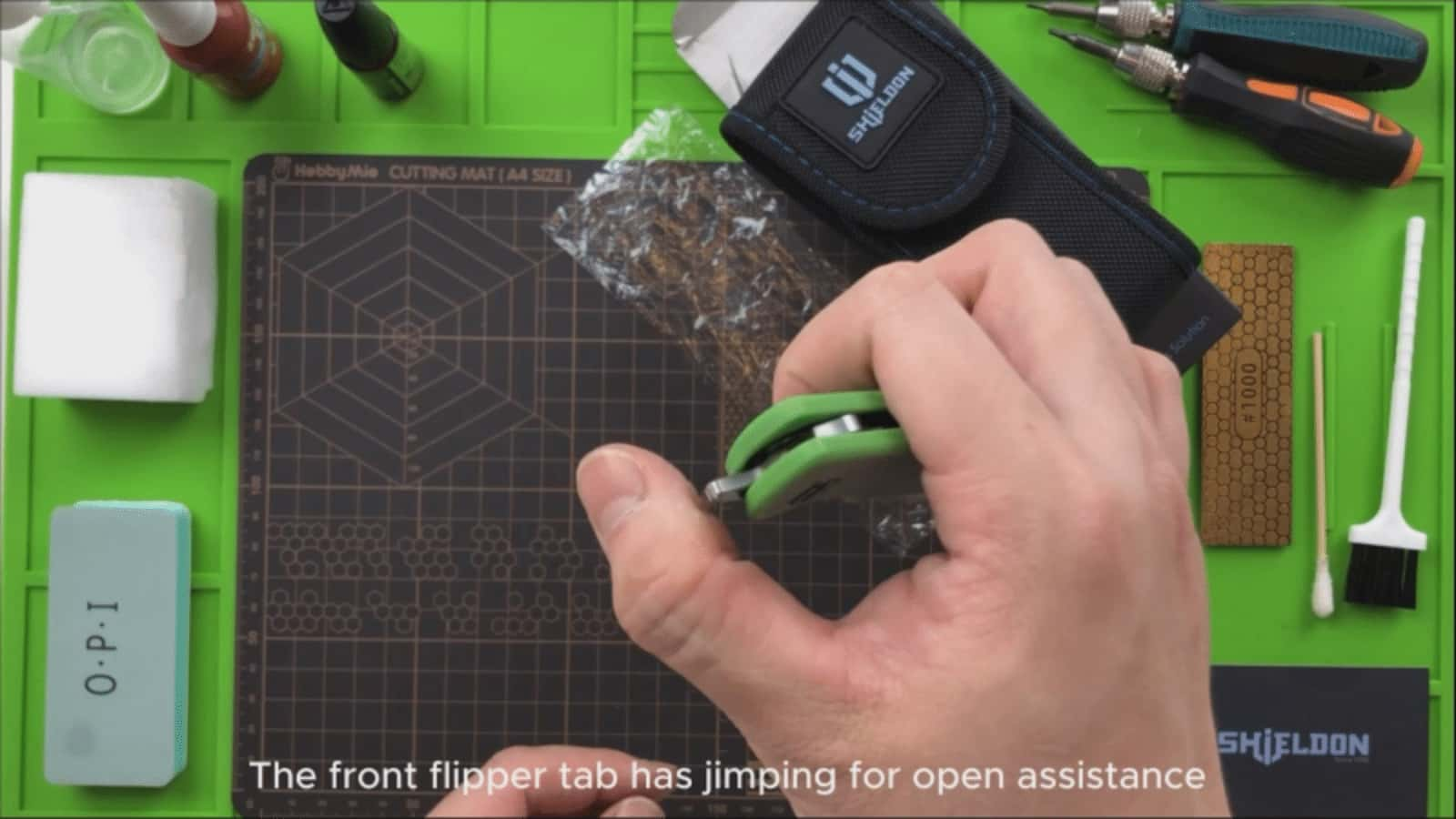

- Jimping on the front flipper tab enhances traction, allowing for easy blade deployment even in wet or gloved conditions.

- T8 416SS hardware ensures uniformity, making maintenance simple. A reversible stainless steel wire pocket clip, finished in satin, supports ambidextrous carry.

- The handle is designed for ergonomic comfort, with a thickness of 0.472 inches (12mm) for a secure grip. The nested liner lock ensures reliable blade security.

- The front flipper tab enhances control and allows for quick, smooth blade deployment.

- The blade is marked with “14C28N,” a steel known for sharpness, edge retention, and corrosion resistance. The stonewash finish minimizes visible wear over time.

- The drop point blade design offers precision and versatility, making it suitable for various cutting tasks. A caged ceramic ball bearing system ensures smooth operation.

- The collaboration between Marcus Williamson and Shieldon expands his design reach, maintaining the essence of his fixed blade in a folding format. The green handle colors symbolize environmental awareness while improving grip.

- Structural integrity is evident in the Stinger’s nested liner lock, preventing any blade play. When closed, the blade remains perfectly centered, showcasing meticulous craftsmanship.

- The Stinger demonstrates secure lock-up with no blade wobble, ensuring stability during use. Its centered blade alignment reinforces its precise construction.

- More than just a folding knife, the Stinger embodies thoughtful design, functionality, and expert craftsmanship. Its lightweight, durable materials make it ideal for both everyday tasks and outdoor adventures.

- Performance testing highlights the blade’s 15-20 degree sharpening angle, allowing for clean, precise cuts across various materials.

- The Stinger translates Marcus Williamson’s popular fixed-blade camping knife into a compact EDC folder, preserving its essence while enhancing portability and versatility.

- The unboxing experience confirms the Shieldon Stinger as a well-crafted, high-performance knife, making it a valuable addition to any EDC collection.

What is the Production Process of Stinger Folding Knife?

- Shieldon has developed a refined production process for brand EDC folding knives and customized OEM/ODM knives. The production steps are nearly identical, with variations based on specific customization requirements. Each production run is handled with precision, as it reflects the brand’s capabilities and strengthens its reputation among OEM/ODM customers. The following details outline the production process of folding knives, using the Shieldon Stinger as an example.

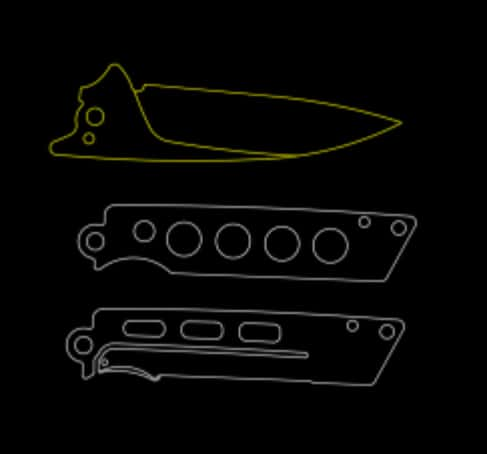

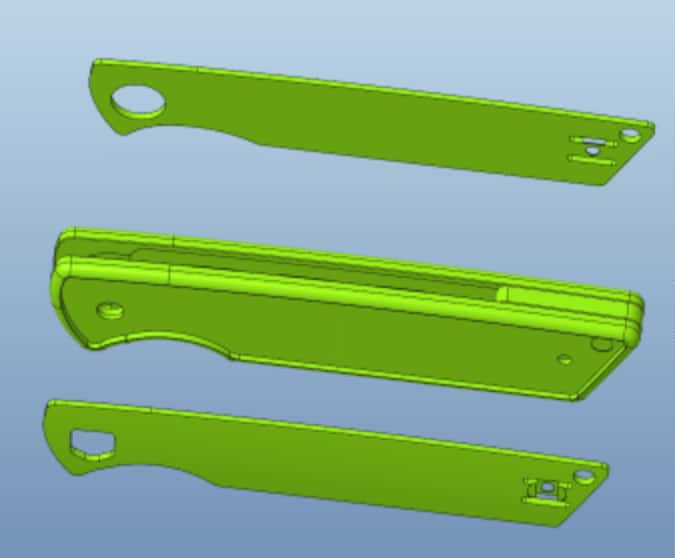

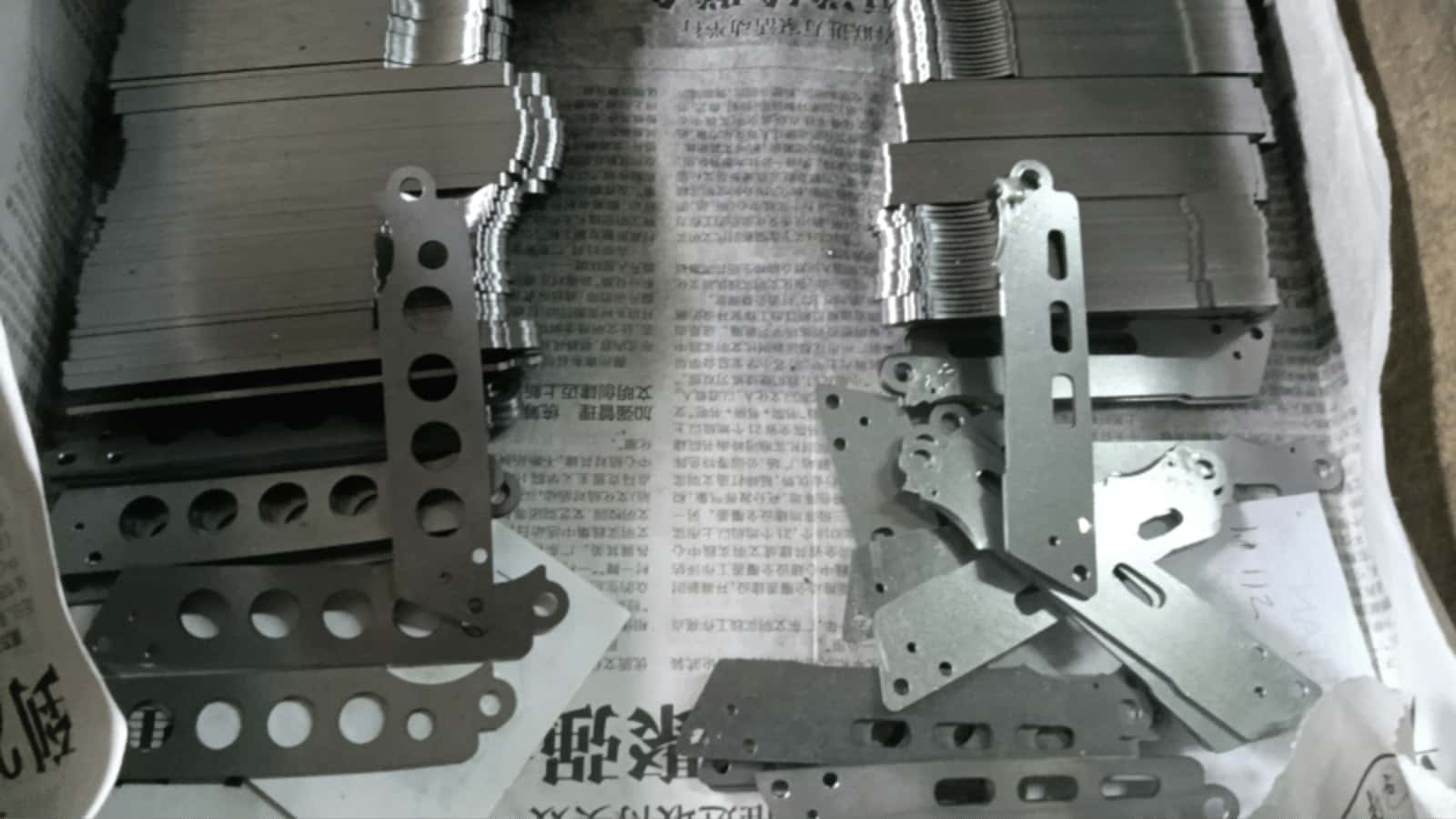

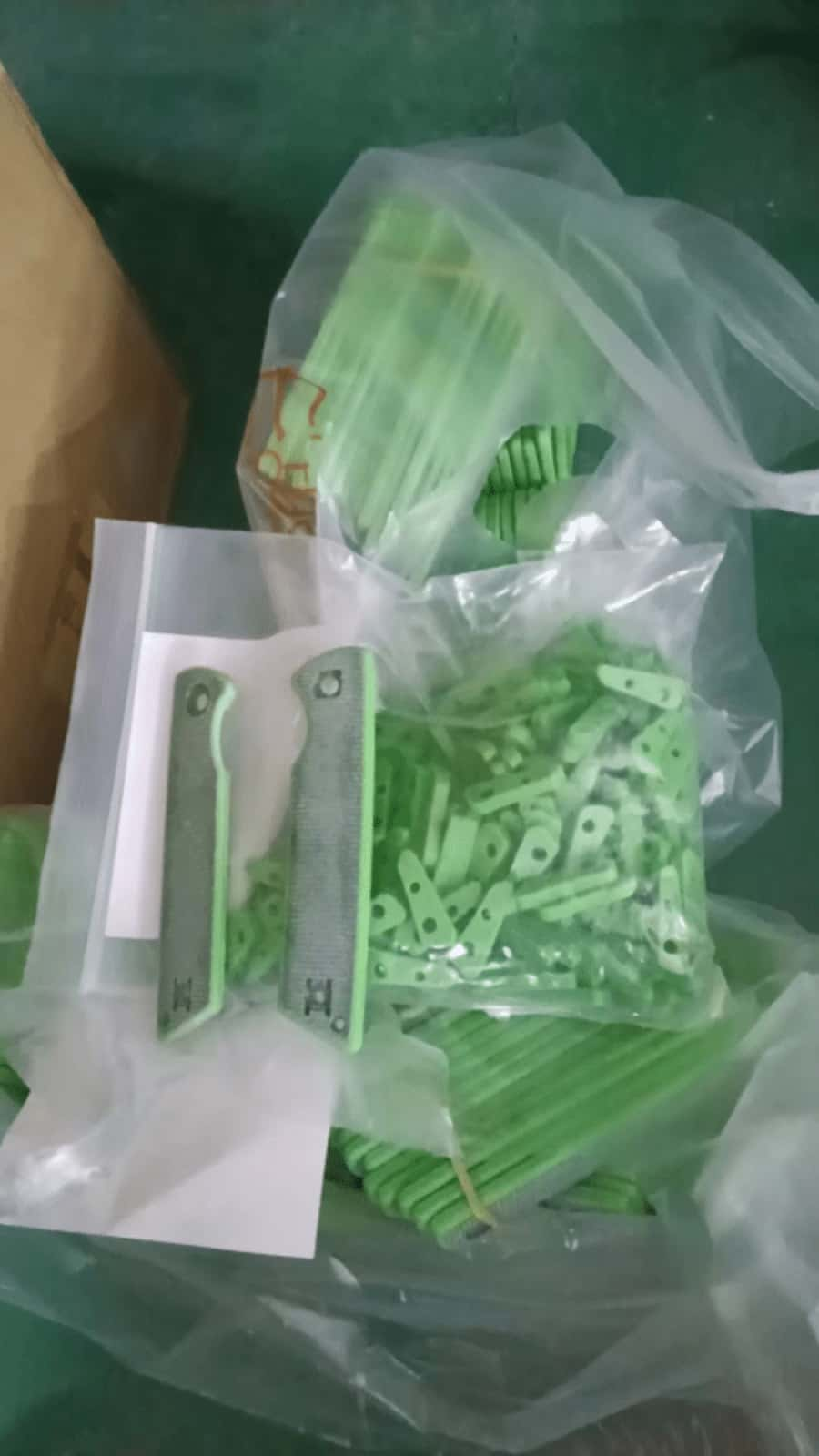

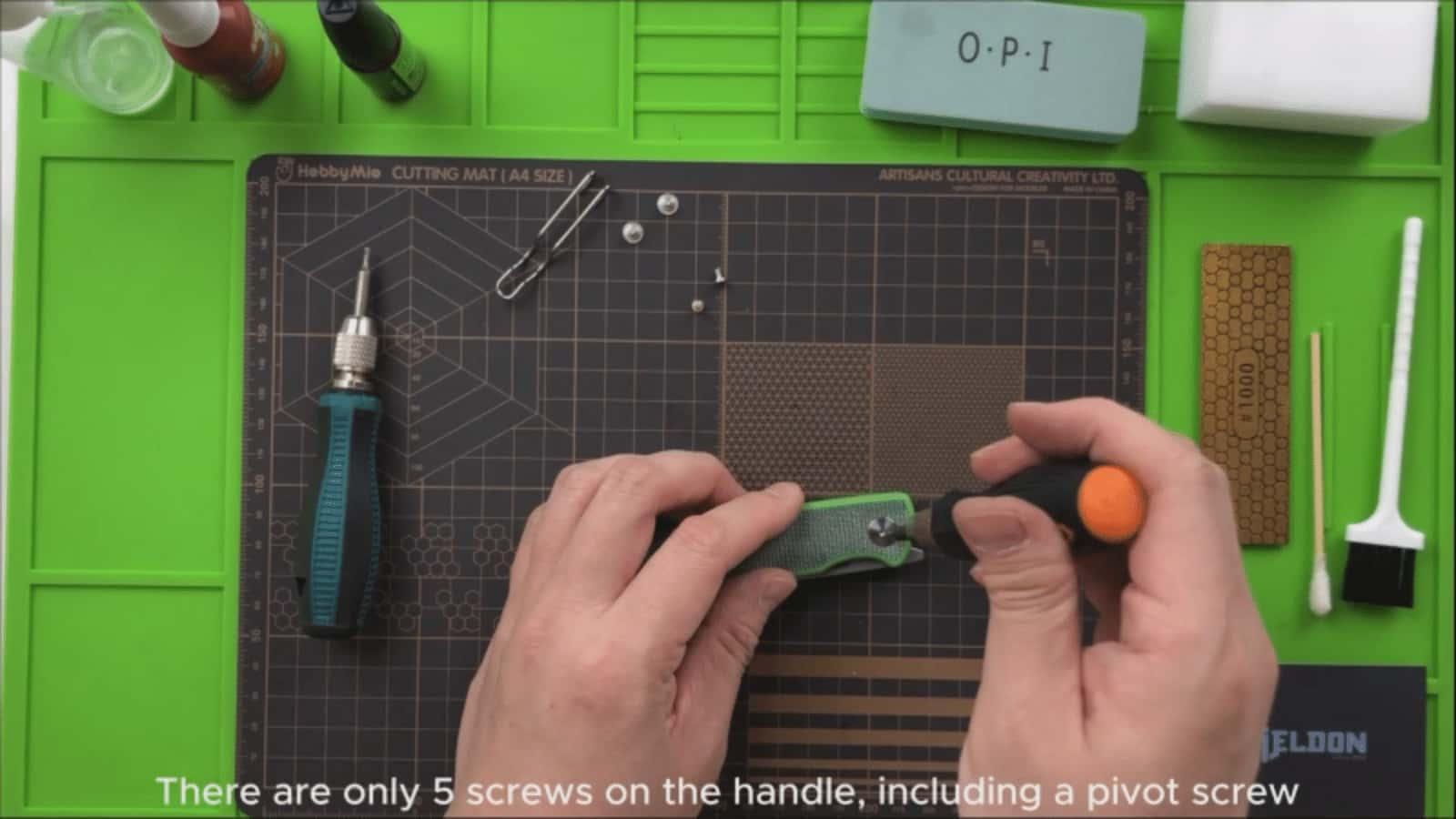

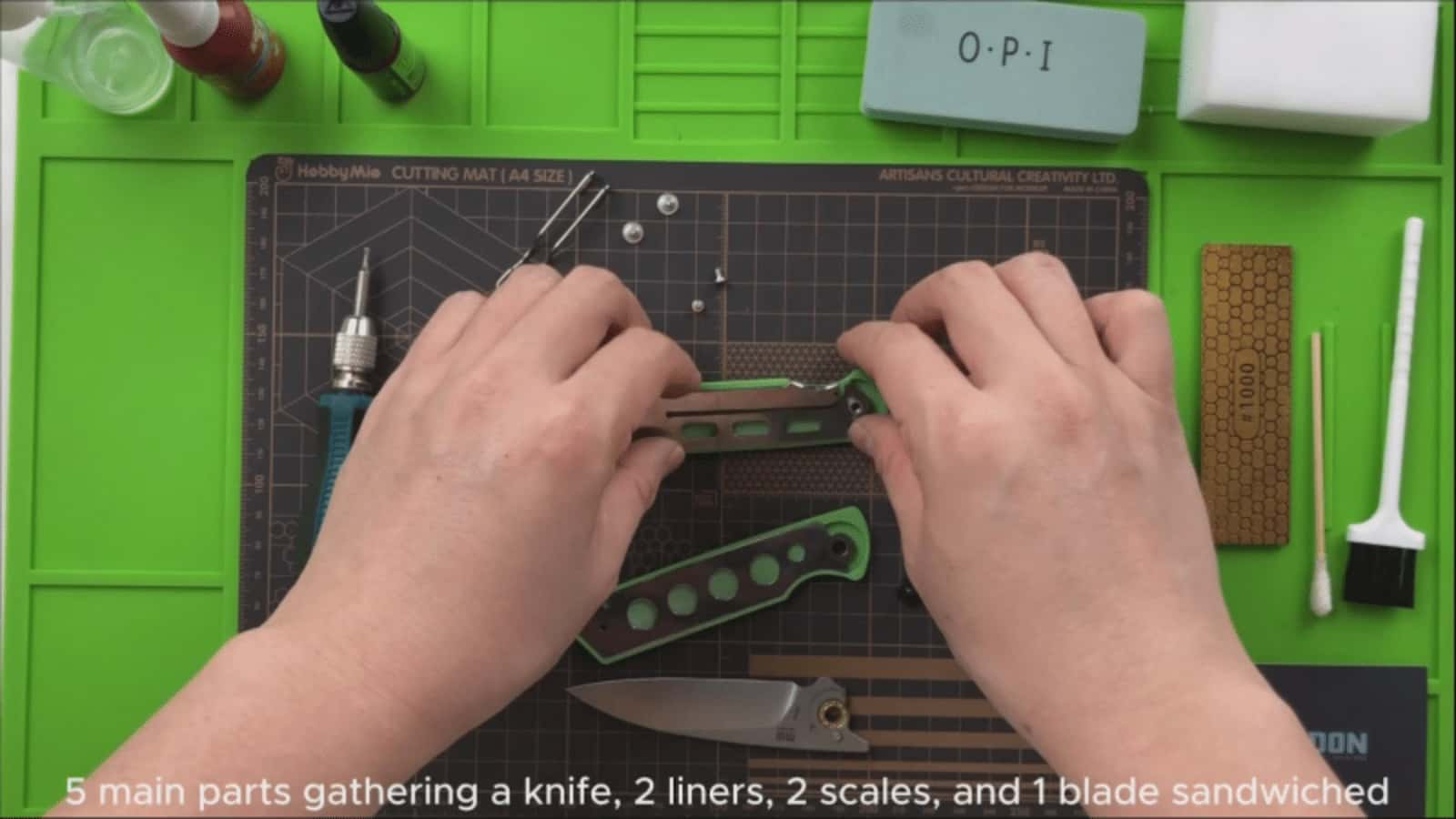

- A folding knife consists of several components, including two handle scales (front and back), two liners (front and back), a blade, a pivot, a clip, and additional accessories such as screws and stand-offs.

Some designs also incorporate a backspacer. Each component is produced individually before assembly into the final product.The image illustrates the front liners, which are skeletonized to reduce weight. Five holes are strategically placed in the liners for this purpose. By maximizing space utilization, unnecessary weight is removed, making the overall knife lighter.

- The image showcases the back liners, which feature a lockbar for the locking mechanism.

This mechanism is referred to as the liner lock. Each production batch contains multiple pieces, sometimes reaching hundreds, due to the minimum order quantity (MOQ) requirement. In the knife and tool industry, production runs must meet an MOQ of at least 200 pieces to offset costs.

Milling data, including the X, Y, and Z-axis specifications, must be programmed into the CNC machine before processing. A worker monitors the CNC milling process to ensure precision. If the MOQ were too low, production costs would not be sustainable, making a minimum quantity essential.

- The image displays blade shapes cut from raw steel material (14C28N plate steel), with approximately 200 pieces produced per batch. Additional blades are often created to account for potential defects during production. These raw blades undergo further processing.

The next step is heat treatment, a crucial process involving controlled heating and cooling to modify the steel’s mechanical properties. This enhances characteristics such as strength, hardness, and durability, improving resistance to wear and corrosion. The process begins with austenitization, where the steel is heated to a specific temperature for uniformity.

Quenching follows, rapidly cooling the material to increase hardness. Finally, tempering reheats the steel at a lower temperature to reduce brittleness while improving toughness.

Heat treatment strengthens the steel, enhances fatigue resistance, and tailors its properties for optimal performance. Due to the confidentiality of this process, no images are available.

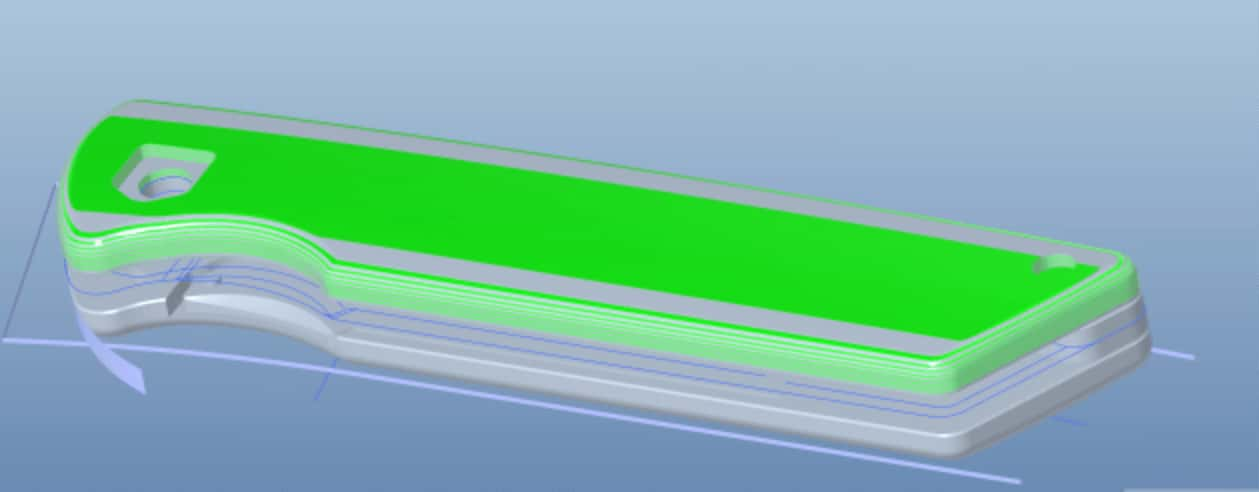

- Once heat treatment is complete, the blade components proceed to CNC machining. This stage involves creating thumb holes, jimping, pivot milling for ball bearings, and screw hole placements.

Machining occurs after heat treatment because the process hardens the steel, making it more difficult and expensive to machine beforehand. Working with pre-heat treated steel ensures precision, minimizes tool wear, and reduces costs.

Additionally, heat treatment can cause dimensional changes and internal stresses, which are better managed post-treatment to maintain accuracy and stability. This sequence results in a cleaner, more precise finish on knife features.

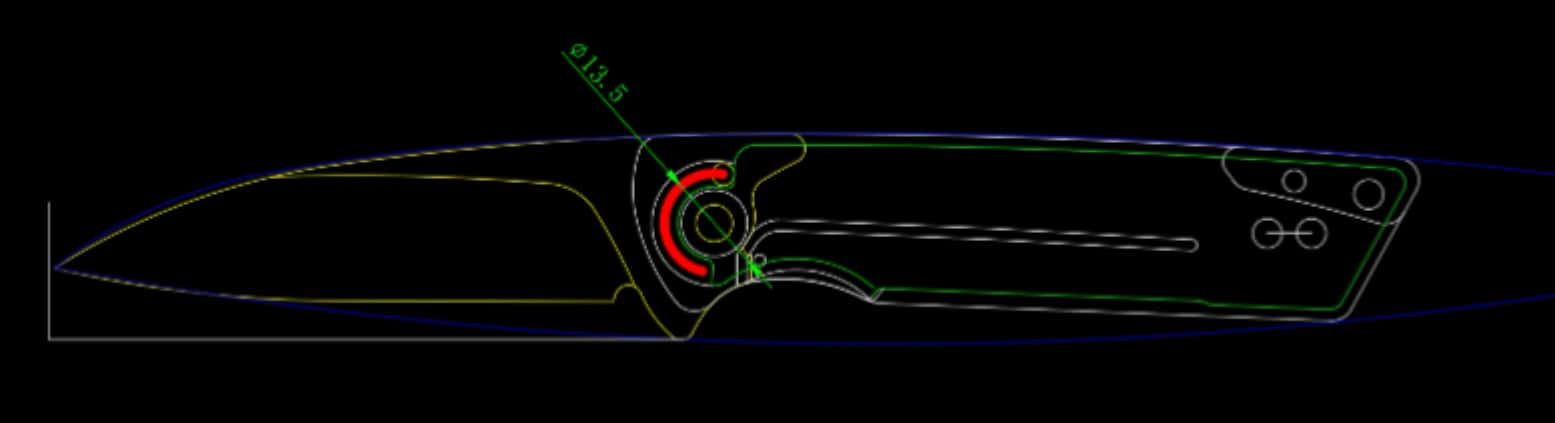

- The image highlights the milled round area on the pivot for ball bearing placement, along with a hole beside it for the stop pin. While this may appear simple, precise CNC programming is required to determine hole size and depth. Controlling the X, Y, and Z-axis of the CNC machine is crucial.

Occasionally, test pieces are sacrificed to fine-tune parameters and eliminate tolerances, ensuring production accuracy. Although CNC machines run automatically, extensive preparation is necessary to guarantee seamless operation. The more precise the setup, the smoother the subsequent steps.

- After CNC machining, the blades undergo water milling, refining the belly area into a “V” shape for enhanced cutting performance. Milling both sides of the blade creates this “V” profile, ensuring smooth cutting and a razor-sharp edge at the tip. This process is critical for precision and sharpness, significantly improving the knife’s overall functionality.

- The image showcases completed handle scale components (front and back) and the backspacer. CNC machining is used for these components, similar to steel processing but executed with different CNC machines. Steel CNC machines require hard, thick drills, whereas G10/Micarta CNC machines use softer, smoother drills.

The drill size can be adjusted based on production requirements. Smaller drill tips (e.g., 0.1mm) produce a finer finish but require longer processing times, increasing costs. Larger drill tips (e.g., 0.5mm) shorten processing times but result in a rougher finish, reducing costs.

Quality classification is based on these factors. For OEM/ODM orders, customization is available to balance quality and cost based on customer preferences.

Like steel production, G10/Micarta production also has an MOQ of 200 pieces per batch, aligning with the steel MOQ. Orders can be placed in multiples of 200 (e.g., 400 or 800 pieces), with larger quantities reducing the cost per unit.

Raw materials for steel and G10/Micarta are prepared accordingly, requiring careful production planning to minimize waste.

- The image presents the front and back handle scales designed for a nested liner lock. This variation of the liner lock enhances strength and structural integrity by reinforcing the lock with the entire handle material (e.g., G10) rather than relying solely on steel or titanium liners. This design improves durability, prevents liner breakage under stress, and offers a more compact, ergonomic grip. The nested liner lock maintains the one-handed operation and reliability of a standard liner lock while providing additional strength and longevity.

- The image illustrates the milled scale surface, designed to accommodate a “shield” pivot screw and a wire pocket clip. Screw holes are also machined using CNC technology. The Shieldon Stinger handle features a Micarta inlay within the G10 surface, serving three purposes: aesthetic appeal, enhanced grip due to Micarta’s anti-slip properties, and protection against Micarta’s tendency to fray if used improperly.

- The image displays backspacers designed for the Shieldon Stinger. Two holes are present for stand-off placement, connecting both sides of the handle. These stand-offs are hidden inside, reducing the number of visible screws for a cleaner design.

- The blade finishing process involves surface polishing, grinding, and coating to enhance aesthetics, durability, and corrosion resistance. Techniques such as stonewashing, bead blasting, and mirror polishing provide different finishes. Some knives receive a protective coating like DLC (Diamond-Like Carbon) or PVD (Physical Vapor Deposition) to increase hardness and wear resistance.

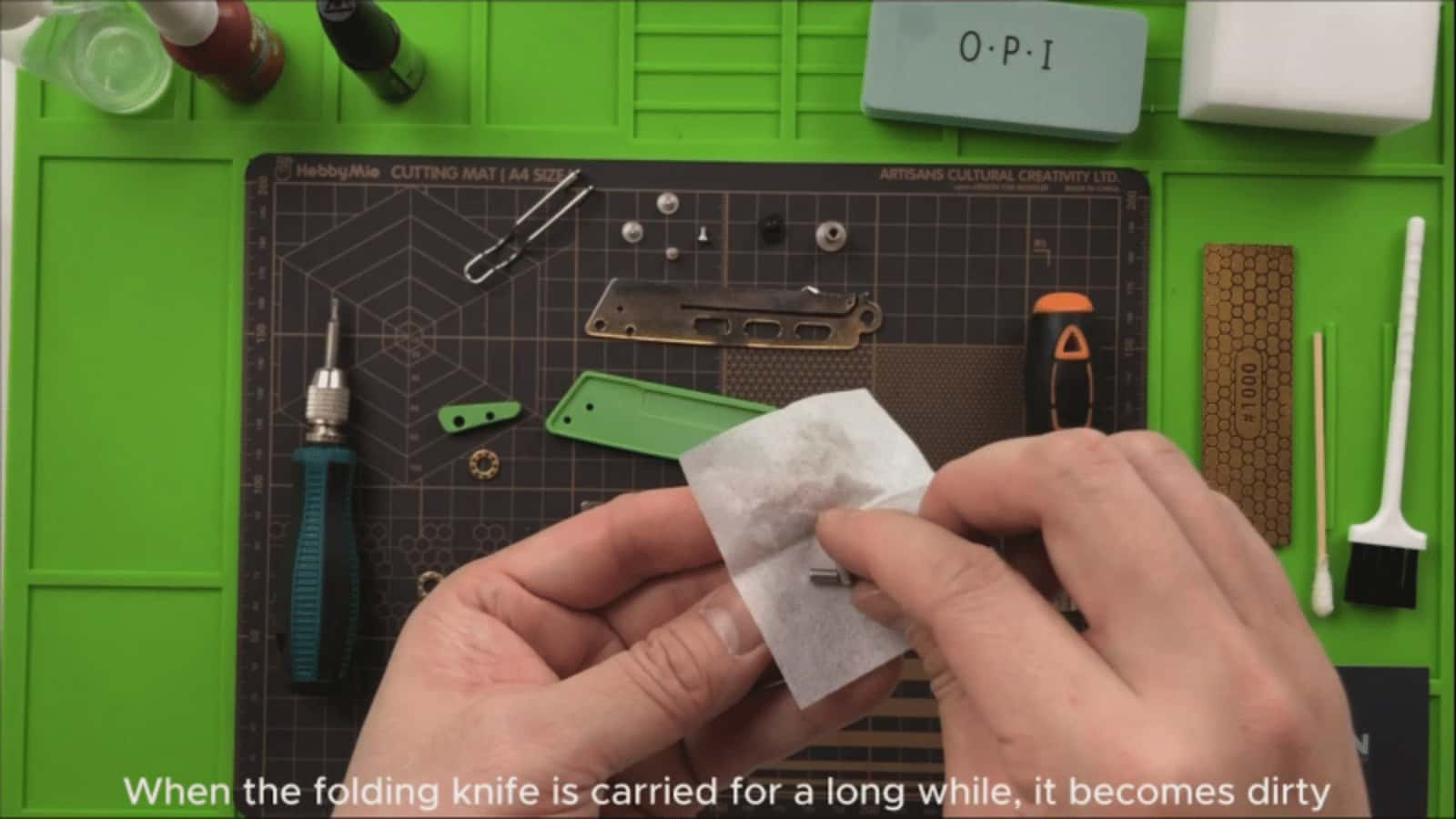

- Final assembly includes installing the pivot, ball bearings, screws, and other small components. The knife is then adjusted for optimal blade centering, smooth deployment, and secure locking. Quality control checks ensure every knife meets design specifications before packaging and shipment.

- From the image, the liners and the blade are ready for assembly. The first assembly is similar to a laboratory experiment. Testing is required to ensure the lockbar fits the blade when opening, the blade is centered to the handle without lock rock or lock play, the liners fit the handle scale without gaps, the backspacer fits the handle scales without protrusion, and the overall deployment of the blade opens and closes smoothly. Every component must be tested during assembly to guarantee proper fit and function.

- Once testing is complete, the next steps include logo engraving and razor sharpening. Laser logo engraving on blade steel is a high-precision process that utilizes a focused laser beam to etch designs or logos directly onto the metal surface. This method is performed using CNC laser engraving machines, which are programmed to guide the laser beam along a specified path, melting and vaporizing the steel’s surface to create the desired engraving. The process is non-contact, which means it does not physically touch the blade, reducing the risk of deformation or damage. Laser engraving offers versatility, as it can be applied to various metals, including stainless steel, and allows for intricate detail work. The principle behind it is the interaction of the laser’s high energy with the metal, which results in localized melting or vaporization, leaving a permanent mark. This technique is valued for its precision, speed, and the ability to create deep, lasting marks that can resist wear and environmental factors.

- Razor sharpening is the final step for safety reasons. Once the blade is sharpened, it becomes dangerous to handle in other steps. To prevent any risk to workers, this step is always performed last.

Razor sharpening involves honing and stropping techniques to maintain a keen and effective blade edge. The process typically begins with honing, where the blade is sharpened against an abrasive surface, such as a whetstone or a sharpening stone, to realign and refine the edge.

This step removes material from the blade’s edge, creating a new, sharper edge. Following honing, stropping is used to polish the edge to a razor-sharp finish. This involves running the blade across a leather strop, which can be in various forms such as hanging, loom, or paddle strops.

The strop helps to smooth out any burrs and further refine the edge, resulting in a blade that is sharp and ready for use. The principle of razor sharpening is based on abrasion, where material is removed from the blade’s edge using a hard, abrasive surface, and then polishing to achieve a keen edge.

Disassembly and Assembly Procedure of Stinger Folding Knife

- Marcus Williamson, the creative force behind the Shieldon Stinger, has redefined the concept of everyday carry. From his design studio in the heart of the USA, he shares the inspirations behind the Stinger, his dedication to minimalism, and the journey of creating a knife that serves as both a companion and a tool.

- The Stinger’s blade is crafted from 14C28N steel, a cost-effective material often used in high-end models without sacrificing performance. Its stonewash finish gives the blade a plain yet refined character, typical of EDC tools. This finish also provides a non-reflective, wear-resistant surface that conceals scratches while maintaining a consistently appealing look. The drop point design lowers the blade’s tip, enhancing safety, precision, and control for various cutting tasks. A front flipper tab with jimping adds grip and control, allowing for quick and secure blade deployment in any condition.

- The handle of the Stinger strikes a balance between contrast and harmony. Featuring a lawngreen G10 handle with an olive Micarta inlay, it combines the durability and moisture resistance of G10 with the natural grip and aesthetic appeal of Micarta. This color scheme enhances both the visual appeal and the functionality of the knife, ensuring a comfortable grip. A nested liner lock integrated into the full handle material provides additional strength and stability, enhancing lock-up security with a reassuring click when the blade is firmly in place.

- Transforming the ordinary into the extraordinary requires vision, and Marcus Williamson has achieved just that with the Shieldon Stinger. This folding EDC knife has garnered attention among outdoor enthusiasts and urban dwellers alike. “A person’s EDC says a lot about them,” Marcus states, as the hum of precision machinery fills his workshop. “Whether opening a letter, cutting a rope, or simply experiencing the satisfaction of a sharp blade, a good knife becomes an indispensable tool.”

- The Stinger is more than just a knife; it is a response to the modern world’s need for a balance between utility and elegance. Designed to fit seamlessly into a pocket, it remains unobtrusive yet ready for the unexpected tasks that arise daily. Like a perfect sketch, a handwritten note, or a paper airplane, the Stinger represents something that technology cannot replicate. This simple yet essential tool bridges the gap between necessity and craftsmanship.

- Equipped with a reversible stainless steel wire clip with a satin finish, the Stinger accommodates both left- and right-handed users. This ambidextrous design ensures accessibility and comfort, making it a practical companion for everyday carry. Additionally, the caged ceramic ball bearing system allows for smooth blade deployment and enhances longevity, ensuring the Stinger remains a reliable tool for years to come.

- Marcus Williamson’s passion for knives began at a young age, passed down by his father, a man deeply connected to the land. “Receiving that knife was a rite of passage,” Marcus recalls with nostalgia. “It symbolized trust and responsibility, an extension of my hand used for everything from fishing to farming.”

- Growing up between rural landscapes and urban settings, Marcus found himself drawn to the simplicity of outdoor life. “Whether spending time in the city or hunting in the countryside, I was always seeking adventure,” he explains. Frustrated with the complexity of many knives available at the time, he was inspired to create something that aligned with his minimalist values.

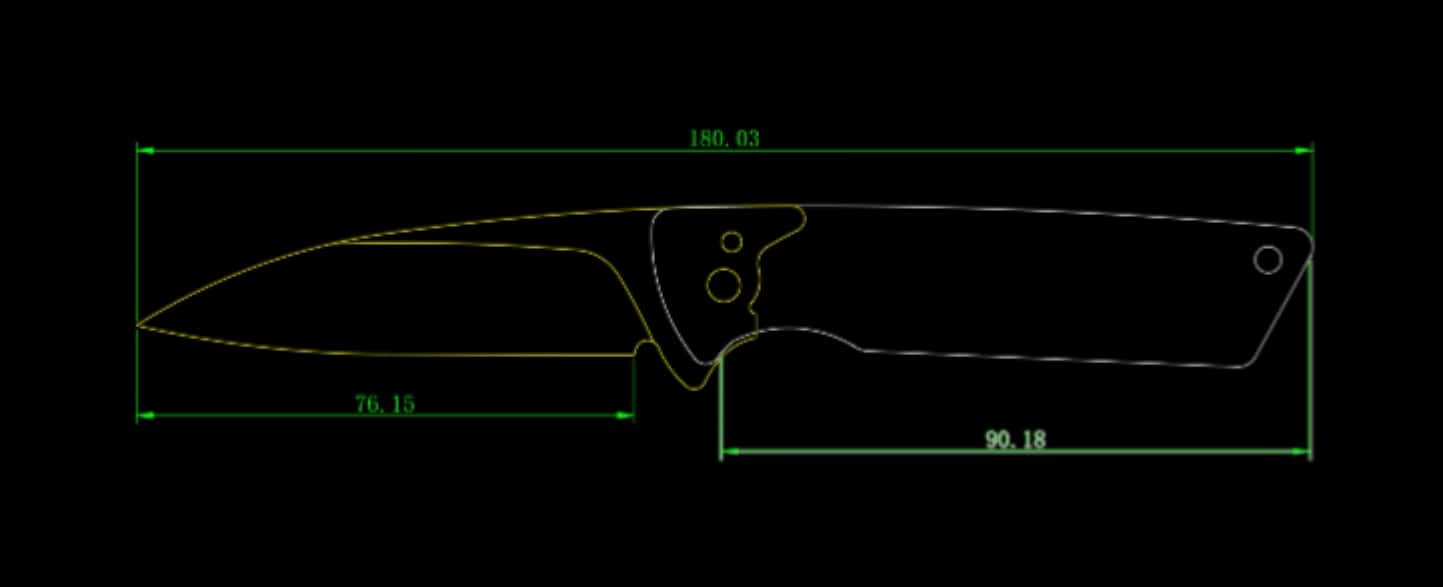

- With a total length of 7.32 inches and a weight of just 2.68 ounces, the Stinger is a lightweight and portable option for daily carry. The blade, measuring 2.95 inches in length and 0.118 inches in thickness, offers a balanced cutting edge that is both strong and lightweight. Every component, from the main pivot hardware to the assembly and clip hardware, is crafted from T8 416SS, ensuring precision and durability in construction.

- In the quiet of his living room, Marcus set out to reverse-engineer the perfect pocket knife by hand. “I wanted to strip it down to its essence, to find the most minimal, straightforward, and clean version of a knife,” he explains. The result was the Shieldon Stinger—a knife that embodies the spirit of reduction without compromising performance or aesthetics.

- More than a year later, the Shieldon Stinger stands as the embodiment of Marcus’s philosophy. It is the newest and slimmest addition to the Shieldon lineup, a slip-joint knife designed to adhere to UK regulations while maintaining both style and substance. Available in straight-bladed and serrated versions, with G10 or aluminum handles and 14C28N steel, the Stinger is as much a work of art as it is a tool.

- The Shieldon Stinger is more than just a knife—it is a legacy. Designed to be passed down through generations, it serves as a symbol of adventure and the memories forged along the way. In an era dominated by ever-changing technology, the Stinger reaffirms the value of simplicity, reliability, and craftsmanship. It is a testament to the idea that sometimes, the best solutions are the simplest ones.

- “The Stinger is so light that it’s easy to forget it’s there,” says one of Shieldon’s friends and photographers, echoing the sentiments of users worldwide. “It’s not just for grand adventures; it’s about being prepared for the everyday tasks that require a sharp blade.”

- Every Shieldon product is designed with the modern adventurer in mind—someone who transitions seamlessly from city life to the wilderness, always prepared for the unexpected. “The goal is to encourage people to experience the world in a more tangible way,” Marcus explains. “The Stinger is for those who are educated, smart, humble, competent, and confident.”

- The Shieldon Stinger is a modern everyday carry knife, built for those who seek adventure and appreciate high-quality gear. It encourages owners to see it as more than just a tool—it is a daily companion, always ready for life’s challenges. With its eco-friendly design, durable construction, and sleek aesthetics, the Stinger reflects the adventurous spirit of its users. More than just a knife, it tells a story—one that is just beginning. As users clip the Stinger to their pocket and set off into the world, they carry not just a tool, but a trusted companion.

- Marcus hopes to inspire younger generations to find personal meaning in the Shieldon story, redefining what it means to be a modern adventurer. “I want to build a brand that lasts, one that truly resonates with people,” he shares. “It’s not about becoming a massive corporation; it’s about the joy of creating something meaningful.”

- From its humble beginnings in Marcus’s living room to a fully realized product with dedicated factory partners and a loyal global customer base, the Shieldon Stingerhas come a long way. “It takes a team to bring a product like this to life,” Marcus reflects, pride evident in his voice. “There are hard days and long hours, but I wouldn’t trade this for anything else.”