The Production Process of a Folding Knife

Making a high-quality folding knife is no simple task. It’s a meticulous process that involves precision, skill, and advanced technology at every step. From crafting the blade and handle to assembling the final product, every detail matters to ensure durability, functionality, and safety. Whether you’re curious about the craftsmanship behind folding knives or want to understand how […]

Packaging Production Process

Every great product needs great packaging. The Packaging Production Process shapes how your pocket knives, multi‑functional tools, and outdoor gear arrive safely—and look irresistible—on store shelves and doorsteps. At Shieldon, leading custom tool manufacturers and wholesale knives suppliers, we know that a seamless packaging journey turns first impressions into loyal customers. In this article, we’ll walk […]

Multi-tool Manufacturing Process

Imagine a craftsman shaping metal and composite, one stroke at a time, forging a versatile multi-tool that fits in your pocket. The multi-tool manufacturing process brings together materials science, precision engineering, and cutting-edge inspection methods to create a reliable everyday companion. From selecting aerospace-grade alloys to laser-assisted positioning during final assembly, every step ensures performance and […]

OBM Brand Distribution

At Shieldon, we believe that knife quality means life. With countless years of experience, we don’t just make knives, we craft reliable everyday carry tools that meet the highest international standards. We know the market changes fast, so we stay ahead by combining the latest manufacturing techniques with deep technical knowledge. If you want to […]

A Comprehensive Guide to the Product Development Process at Shieldon

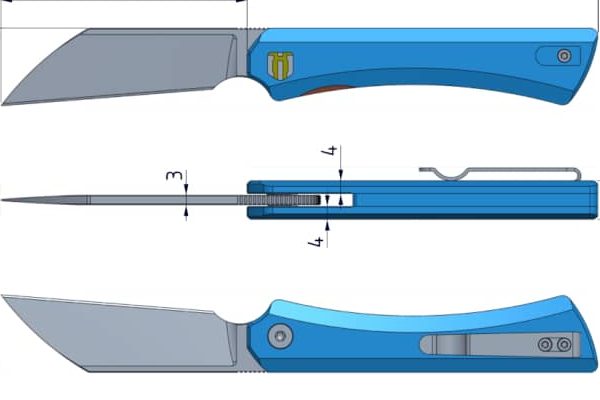

Shieldon offers a clear and efficient product development process to bring ideas to life. Starting with a confidentiality agreement, each stage is carefully managed to ensure quality and meet client requirements. The process begins by confirming product needs like functionality, materials, and certifications. Detailed design and engineering follow, including 3D modeling, material selection, and prototype […]

걸작 공개: MP01 Blacksmith Rain의 매혹적인 창조물을 목격하십시오.

Mp01 Blacksmith Rain의 제조 과정 이야기 Michael Pretsch와 Rain의 탄생 – Shieldon의 상징적인 EDC 나이프” 칼이 단순한 도구 이상의 영역에서 Michael Pretsch라는 이름의 카리스마 넘치는 디자이너가 등장했습니다. 지난 5년 동안 그는 칼 디자인 기술을 탐구하고 […]

Blacksmith Hierophant MS01A 나이프의 포괄적인 설계 프로세스

Blacksmith Hierophant MS01A 칼은 Matthew Szymanski와 Shieldon이 세부 사항에 최대한 주의를 기울여 설계하고 제작한 독특하고 혁신적인 제품입니다. 설계 프로세스는 포괄적이었으며 전통적인 기술과 현대 엔지니어링 원칙을 모두 통합했습니다. 재료 선택에서 최종 테스트 및 연마에 이르기까지 모든 단계는 [...]

Shieldon과 Eric Garza의 Blacksmith Viper EG01A 칼 제작 과정

전문 칼 사용자 및 제조업체인 Shieldon과 Eric Garza는 고품질 칼을 갖는 것의 중요성을 이해합니다. 칼 사용자에게는 어떤 상황에도 대처할 수 있는 칼이 필요하고 칼 제조업체에게는 엄격한 테스트를 반드시 통과할 수 있는 칼이 필요합니다. 그것이 그들이 Blacksmith Viper를 만들기 위해 팀을 이룬 이유입니다. [...]